Power Plant Ultrapure Water Market to Reach $35 Billion In 2015

There are three major water treatment processes in power plants: Pure water for steam, Cooling water and Wastewater.

McIlvaine

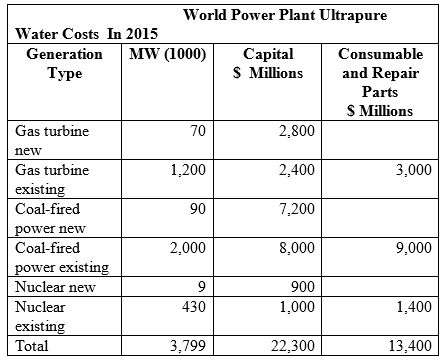

The process for purifying water for steam generation is referred to as ultrapure water. Power plants around the world will spend over $35 billion on new and existing ultrapure water systems in 2015. This is the prediction in McIlvaine Ultrapure Water: World Market.

Coal-fired, gas turbine combined cycle, nuclear and concentrated solar power plants all use the same technologies for purifying the water which is converted to steam to drive the electric generator. The major difference is that only a portion of the power is derived from steam generation in gas turbine combined cycle plants. However, there is a unique additional need for ultrapure water in some gas turbine plants. In dry hot climates, water is introduced through fogging nozzles to reduce the inlet air temperature to the turbine.

The system includes a series of processes starting with purification of the raw water. Particulate soluble species and gases are removed. High purity is needed to avoid fouling in boiler tubes as well as high temperature corrosion. Treatment is required both for the new water entering the cycle and for the condensed steam. Equipment requirements are filters, piping, pumps, valves, ion exchange or electrodeionzation units, feedwater heaters, deareators, degasifiers, condensers and instrumentation.

Coumsumables and repair parts include chemicals, seals, membranes, cartridges, pump and valve parts, sensors, I.E resins, nozzles, packing, etc. Corrosion inhibitors and anti scalant chemicals are a significant portion of the total.

Due to the activity in Asia, the investment in ultrapure water systems for coal-fired power plants in 2015 will exceed that of nuclear and gas turbine combined cycle plants combined.

Source: The McIlvaine Company