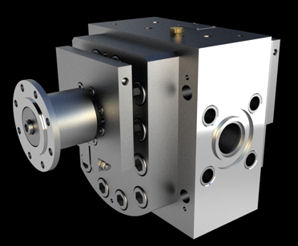

New Maag Gear Pumps for Modern Extrusion Processes

Demand is increasing for gear pumps designed for high-pressure applications. The trend is being driven by the increased amount of applications involving highly complex processes.

Trudex gear pump from Maag for high-pressure extrusion applications

This includes the modern foam processing used for materials-efficient foam pipes as well as blow film processes. The use of modern filter equipment for ultraclean plastics also requires increasingly high pressure levels during extrusion.

That s why Maag introduces its new generation of the trudex series.

The hallmark of this trend is extrusion equipment working with operating pressures of >120 bar. The pressure at the tool itself is even as high as >400 bar. The trudex series provides a consistent solution to processors working with modern extrusion processes.

Reliability as a principle

The new generation features a new gear geometry promising a higher degree of efficiency for the pump. The pump bearing was also modified to increase its emergency running property.

Process-oriented optimisation

Various tempering options, including the choice of electric or fluid media, cover all process-related requirements of extrusion applications. Maag also offers special configuration of the pump to match a specific customer requirement profile as an optional service.

Source: Maag Pump Systems AG