New Control For KMT High-Pressure Pump

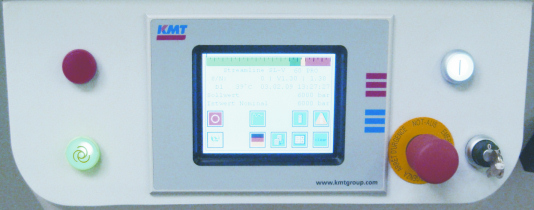

The SL-V 30-100 ultra-high pressure pumps and the models of the SL-V 150/200 range are now equipped with a touch screen control panel.

The new interface is easy to operate and allows for the control and monitoring of all operating parameters by simply pushing the respective buttons on the display. The pump is controlled by a programmable local control (PLC) system. It provides comprehensive functions for the identification and elimination of faults. The key features of the touch screen interface include:

- Easy setting and monitoring of all operating parameters.

- Scale display of the high-pressure pump utilisation.

- Simple integration into synchronised circuits of high-pressure pumps operated in a networked pump system.

- Indication of operating hours of each packing seal for preventive replacement.

Multilingual interface with eleven languages

The interface is available in several languages. We currently offer eleven language versions: German, English, French, Spanish, Italian, Swedish, Finnish, Polish, Czech, Russian and Chinese.

Unit options

Operators in different regions of the world prefer different units. The new touch screen control system caters for this by displaying pressures in bar or psi, volumes in litres or gallons and temperatures in ° Celsius or ° Fahrenheit.

Complete event log

The event logs inform you of all events and their frequency. The menu history shows all event messages, including date and time of occurrence. The list below contains some of the 24 available event parameters:

- Pump operation – switch-on frequency of pump

- Oil temperature fluctuation – frequency of overtem¬perature/undertemperature

- Oil level fluctuation – frequency of oil level dropping below min. mark in oil tank

- Pump pressure fluctuation – pump excess pressure frequency

- Tripping frequency of soft starter motor protection relay

- Battery monitor

- Excess stroke frequency of intensifier and direction of excess stroke

- Frequency of pump switching to recirculation mode to cool hydraulic fluid

- Water inlet pressure controller – frequency of water inlet pressure dropping below 2 bar / 30 psi

- Booster pump pressure controller – frequency of water outlet pressure dropping below min. pressure of booster pump

Efficient detection of causes of faults

The history log is an indispensible tool for the detection, identification and elimination of faults and their causes. It lists all fault events, including date and time of the occurrence. By filtering events in the log, the occurrence and frequency of a specific fault or error message can be analysed in detail. Possible fault messages are shown in the "Possible fault messages" list.

The history log can be transferred from the memory card to an external PC or USB memory stick. This enables operators to request instant support from the KMT Waterjet experts by e-mail alert.

Source: KMT Waterjet Systems Inc.