Netzsch: Special Rotary Lobe Pumps Meet Even the Strictest Legal Requirements

Every commercial and industrial company in Europe is subject to a multitude of regulations for the protection of staff, users and the environment. This not only affects the manufacturing machines themselves, but also the pump systems being used.

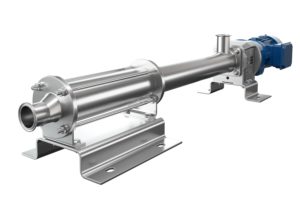

An all-metal design of the T.Proc was fitted, due to the aggressive medium and the high conveying temperatures. (Image: Netzsch)

One of the market leaders in this area, Netzsch Pumpen & Systeme, therefore designs and makes all its systems, ensuring that the standard designs already meet the various European and international directives. The company has a total of 106 certificates, including those for energy efficiency up to IE 4, along with FDA and BfR approvals. Even particularly strict requirements can reliably be met using special types of pump or optional adaptations. At the start of 2014 a major chemical producer was thus supplied with a T.Proc rotary lobe pump to convey corrosive fatty acid, which is not only ATEX-compliant, but also complies with the TA Luft air quality specifications.

It is above all the cosmetics industry and the paint and varnish industry which use fatty acids in their production processes. Depending on the chemical composition, concentration and volatility, the acids can burn the skin or even the respiratory tract, if there is no protection against contact. The medium therefore comes under the area of the Technical Instructions on Air Quality (TA Luft), which contain emissions and immissions limit values, not only for gases, but also for all types of hazardous substances and environmental pollutants. They stipulate that fatty acids must not come into contact with the atmosphere. The existing geared pump, which the manufacturer had been using up to this point to feed its tankers, was no longer able to meet this requirement and therefore had to be replaced.

All-metal pump for aggressive fatty acids

In addition, the sticky and temperature-sensitive medium has to be conveyed at 70°C to keep it free-flowing. At the same time, the installation area is Ex zone 1 due to possible gas accumulations, which means the pump has to be ATEX-compliant. In order to fulfil both regulations, TA Luft and ATEX, at the start of 2014 the operating company had a rotary lobe pump of the T.Proc type installed which was specifically developed for this kind of difficult media. An all-metal design was chosen due to the aggressive substance and the high conveying temperatures. The high-strength steel used for this is extremely resilient, which ensures a long service life for the pump. In addition, this material enables manufacture with very small clearances between the rotary lobes and the housing, which gives a high level of efficiency.

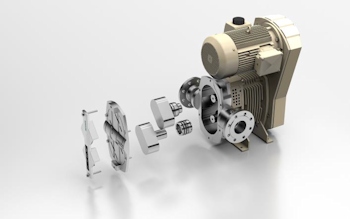

The pump, which is part of the Tornado T2 series made by Netzsch, is based on proven displacement technology and works with two straight bi-lobe rotors. Firstly, this form has the advantage of creating a large free ball passage, thus ensuring problem-free conveyance. Secondly, it means the rotary lobes can be quite easily dismantled from one another for cleaning or inspection. The backflow is also kept particularly low thanks to the long sealing line. In spite of the straight rotary lobes, with this type of pump the pulsation values are at a similarly low level to those designed with complex spirals and multiple lobes. This is achieved using the Netzsch Pulsation Reduction System (PRS), a special adaptation to the geometry of the pump chamber.

Hermetic encapsulation thanks to double-acting mechanical seal

The whole pump structure is designed for robustness, operational reliability and the lowest possible maintenance costs in line with the Service in Place principle. For this reason, the T.Proc is fitted with a large front cover which can be removed with just a few turns of a screw. This means you can easily access the whole interior. The pump chamber itself is designed to be free of dead spaces, to prevent build-up of product and simplify cleaning. Even the rotary lobes are fixed using easily accessible taper lock ringsets on the outside of the housing, so that their rears remain smooth and do not provide any surfaces for the medium to adhere to. This type of mounting also means they can quickly be disassembled and then refitted without any special tool being needed. A setting and installation gauge integrated into the cover makes it easier to achieve the correct positioning in this process, with axial installation work or the checking of keys not being necessary. The sliding surfaces of the shaft sealings are also flush with the rear of the rotary lobes in the pump chamber leaving no dead spaces and are constantly rinsed by the medium, which minimises the risk of blockages.

In order to ensure the hermetic separation of the fatty acid being conveyed from the surrounding atmosphere required by the TA Luft air quality specifications, the Netzsch experts fitted a double-acting mechanical seal with a pressurised flushing system. The seal is permanently lubricated from the attached quenching pot, which prevents clogging and offers greater reliability than a single-acting seal, with which only the installation space would be filled with oil. The mechanical seals of the T2 series have a cartridge design and always fit into the same seal housing irrespective of their type, which means no modification work is needed on the pump for the use of this special form. The pre-set mechanical seal is easily fitted onto the shaft along with the rotary lobes during assembly.

Resilient and space-saving drive

The T.Proc is driven using a synchronised belt drive, which is significantly more robust and less prone to breakdowns than the conventional, complex timing gear. Should a fault nevertheless occur, you only have to undo two screws to be able to remove the toothed belt and replace it. The downtime is therefore reduced to a minimum. This technology does not require any extensive spare part stock either, because the efficient sub-assembly only involves a small number of components. The continuous hard-soft contact between the belt and gear wheels also ensures very smooth running of the whole drive and reduces vibration, which protects all the pump s components. Furthermore, the belt drive works completely without oil, which means that time-consuming oil changes and leaks which are harmful to the environment are ruled out.

The unusual drive form does however have another benefit: the belt provides both power transmission to the shafts and also synchronisation of the rotary lobes. Thanks to this double function, the drive only needs very little space, especially as the motor can also be flange-mounted above the conveying chamber if necessary. This means the pump is considerably more compact and around 30% lighter than comparable models. This offers more scope when installing the system and enables it to be used even in cramped conditions – a factor that had an effect in the fatty acid manufacturer s loading area too, because there would scarcely have been enough space for longer pumps here.

Suitable for Ex zone 1

Compliance with the regulations for explosion protection zone 1 was even more crucial than the space issue here. It was possible to use the T.Proc without any risk, because it has ATEX certification for ambient temperatures of up to 60°C and medium temperatures of up to 100°C, like all Netzsch T2 pumps. The basis of this is the in-built ignition protection and the liquid immersion of the systems which qualify them as explosion-protected equipment of classes I M2 c and II 2GD IIC T4. The pumps can even be heated in an ATEX-compliant way using a hot water circulation hose running through the pump cover, if this is required. In this specific application involving fatty acid conveyance, the operating company installed an electrical heating band instead of this, to prevent hardening of the medium in the pump housing. This required a separate EX protection certification.

Meanwhile, the pump has been reliably doing its job for several months and filling the manufacturer s tankers at a volume of 20 m³/h and a pressure of 2.5 bar. In doing so, all the legal requirements have been strictly adhered to, including the TA Luft air quality specifications.