Major Order from German Chemical Company

In August and September 2008, KSB Aktiengesellschaft, Frankenthal, Germany, received several orders worth several million euros for pumping equipment for a new plastics producing plant situated at the industrial park of Höchst near Frankfurt/Main, Germany.

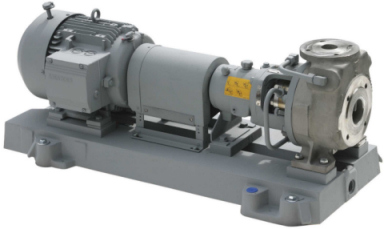

Example of the CPKN-Hs type series built at KSB s Pegnitz factory similar to the ones to be used at the new plastics factory at the industrial park of Höchst near Frankfurt/Main, Germany.

The order is for 102 standardised chemical pumps, 18 non-clogging impeller pumps and six process pumps for high-temperature applications. The order further includes 46 seal-less pumps and seven axially split cooling water pumps. The latter have drive ratings of up to 780 kW.

Most of the pumps intended for the production plant will be manufactured from different types of highest grade corrosion-resistant stainless steel. They will be driven by 2- or 4-pole electric motors, the largest of which with a power output exceeding 355 kW. To stop the flow of plastic material polymerising before it is discharged by the pumps, most pump casings will be fitted with a heating jacket to prevent the medium from cooling off prematurely.

The planned extension of Frankfurt airport forced the chemical company to move its production facilities away from Kelsterbach. However, the need to relocate the production plant opened up the opportunity of enlarging the plant’s production capacity, so that the client decided to largely rebuild his plant from scratch at the new location. The start of production is expected for June 2011; after that the company plans to produce approximately 140,000 metric tons of plastic material per year. These will be supplied for the most part to the consumer goods industry and for manufacturing components for medical apparatus, domestic appliances and for the automobile industry.

The pumps will be supplied in several lots in the summer of 2009. One of the reasons for placing the order with the pump manufacturer were the positive experiences the plastic materials manufacturer had made with KSB pumps in the past. What also tipped the balance in favour of KSB was the fact that KSB’s Pegnitz foundry was able to meet the stringent quality requirements in terms of the materials.

Source: KSB SE & Co. KGaA