Long-distance Runner: New Vane Pump SP 140 FZ

So far, diaphragm pumps have dominated in the sphere of gas analyzers. With the very durable vane pumps of the FZ range from Schwarzer, there is now an interesting alternative.

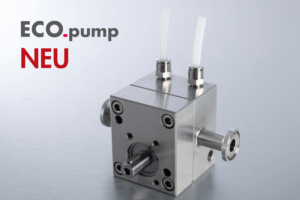

New Vane Pump SP 140 FZ (Image: Schwarzer Precision)

Due to their design principle, vane pumps (rotary vane pumps) have yet had a disadvantage: abrasion in the rotor and stator by the friction of the vanes. Wear and increasing leakage in the pump chambers are the consequences. Already with the last year\ s models, Schwarzer could completely eliminate this disadvantage by optimized manufacturing processes and the use of new materials. The company has now succeeded in improving the service life of its FZ types by another 30%.

Thanks to the use of high-strength vane material and an optimized matching between the friction partners, Schwarzer managed to further reduce the friction coefficient in the pump head. For an adequate driving of this almost wear-free pump unit, bell-type armature motors with a long service life are now used.

At one go, the manufacturer added a new vane model to its product range: The SP 140 FZ excels by higher flow rates and is suitable for operating voltages from 4.5 to 12 V. These new FZ models can also be used in extreme environmental conditions – they reliably deliver even at -40°C.

Furthermore, the vane pumps also stand out due to freedom from pulsation, a low-noise and low-vibration operation, a very low power consumption, a linear characteristic with excellent controllability and small outside dimensions.

In particular in portable gas analyzers, the new FZ types are far superior in a direct comparison to diaphragm pumps. Thanks to their pulsation-free gas delivery, they work excellently in combination with sensitive measuring sensors. This eliminates the need for pulsation-reducing measures (upstream nozzles, for example). The result: Power consumption can be kept to a minimum, no costs for additional components and smaller battery packs. Moreover, linear fitting dimensions and the hose connection on the face allow a considerably compacter design of small gas analyzers.