Flowserve Supports Pfizer in the Production of COVID-19 Vaccine

During the engineering runs of vaccine production Pfizer needed immediate support to replace a mechanical mixer seal on its COVID-19 vaccine production line. Flowserve understood the urgency of the situation and the Flowserve Kalamazoo, Michigan team expedited the rebuild of this critical equipment. “Pfizer has been a Lifecycle Advantage customer since 1997, and now more than ever, we were pleased to be given the opportunity to let the experience and commitment of our associates support Pfizer’s immediate needs as they developed and deployed a COVID-19 vaccine,” said Scott Rowe, Flowserve president and chief executive officer.

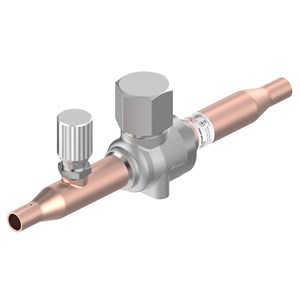

Additionally, Flowserve through its channel partner, Corrosion Fluid Products, is providing Pfizer with a cryogenic valve application to support their expanded production capabilities of the COVID-19 vaccine. The Flowserve Cookeville, Tennessee facility will supply Pfizer with more than 200 Worcester cryogenic ball valves that can handle the rigorous temperature requirements needed in supporting the mass production of the COVID-19 vaccine.

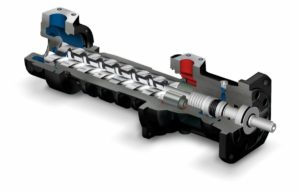

And finally, Flowserve’s Chesapeake, Virginia and Itzehoe, Germany pump manufacturing facilities are providing pumps to Pfizer for both their North American and European vaccine production.

“We are extremely pleased to support Pfizer with our full portfolio of products and services during this critical time in the global fight against the COVID-19 virus,” said Rowe. “As with all of our customers, we strive to be a trusted partner, one they can turn to for critical product expertise, engineering and design support in their time of need. This is a true example of that type of partnership and one that will have a significant impact across the globe.”

Source: Flowserve Corporation