District Energy Growth Drives Tremendous Opportunities for the HVACR Industry

District Energy Growth Drives Tremendous Opportunities for the HVACR Industry (Image source: Armstrong Fluid Technology)

As a single source of heating and cooling for multiple buildings, District Energy installations worldwide typically reduce primary energy demand in heating and cooling by 50% and can achieve operational efficiency of up 90%, according to the United Nations Environment Program.

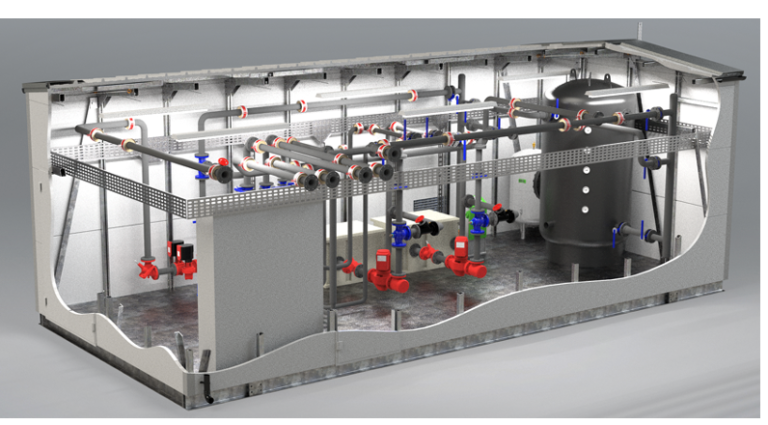

These impressive results are made possible in part by fluid flow technologies designed by HVACR manufacturers such as Armstrong Fluid Technology. Intelligent fluid management systems (iFMS) can now integrate superior pump and control technology into a single packaged solution that can save 30% or more over other parallel pumping configurations. Energy savings can exceed 70% compared to a constant speed system.

Modern variable speed controllers integrate with building BMS systems to provide best efficiency modulation and staging while serving as many as 16 zones.

Armstrong was recently involved with two municipal District Energy Heating Systems in Europe that contributed to an estimated 70% and 45%, respectively, in energy savings to the two projects using the technology described above.

Rambervillers District Heating Eco District

Rambervillers, a village in northeastern France with a population of 20,000, has captured steam from a nearby waste-to-energy plant and converted it into hot water for homes and businesses. As an integral element of the project, Armstrong installed an innovative Design Envelope Intelligent Fluid Management System that integrates pumps and controls and a Design Envelope Integrated Pumping System. Together these technologies reduce pump energy by 30% or more compared to standard pump-sequencing systems.

Sarrebourg District Heating System

The French municipality of Sarrebourg wanted to reduce the territory’s dependence on fossil fuels by creating a hot-water district heating system using wood heating to provide heat and domestic hot water to nearly 3,000 residential and commercial buildings. Using a 5MW biomass biomass boiler as the heat source, the new system will avoid the emission of more than 123,000 tons of CO over the next 20 years. By supporting the project with Design with Design Envelope solutions, Armstrong contributed to overall energy savings reducing pump energy by 70% compared to a constant speed system of similar size.

Enwave Chicago

Enwave Chicago currently operates the world’s largest interconnected district cooling system serving 45 million square feet of space in more than 100 buildings in downtown Chicago. Using thermal energy storage from Lake Michigan water, the system reduced its peak electric demand by 30MW resulting in significant energy cost savings.

Armstrong supports the efficiency of the Enwave Chicago system with a large number of Design Envelope pumps.

As demand continues to grow for District Energy Systems worldwide, the opportunities for innovative HVACR fluid flow systems and solutions will continue to mushroom as well, predicts Tony Furst, RSEC Manager – US Application Engineering, Armstrong Fluid Technology.