Dispensing in Microlitres Range for Telecommunications Engineering

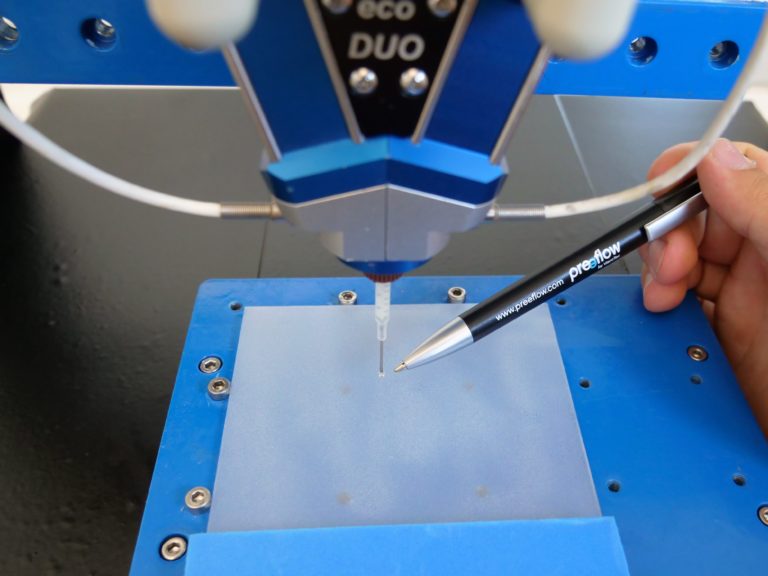

preeflow eco-DUO330 during the dosing tests. (Image source: ViscoTec Pumpen- u. Dosiertechnik GmbH)

More precisely, the tests focused on the bonding of optical fibers in a connector. The customer's requirements were: A repeatable application of 5 µl of a two-component material in a mixing ratio (volumetric) of 8.5:1. Using an eco-DUO330. The material to be dosed is the epoxy adhesive EPO-TEK353ND. A two-component, high-temperature epoxy specially developed for semiconductor, hybrid, fiberoptic and medical applications. The material has already proven itself in many applications worldwide.

The special challenge in dispensing the adhesive is the repeatable dosing and precise interaction of all components for an exact mixing ratio to ensure perfect curing.

The optical fibers used in telecommunications engineering require the highest quality standards. This begins, among other things, with the bonding of the connectors. The preeflow customer's products are used wherever data must be transmitted quickly, reliably and absolutely error-free. For example, in the communication of audio systems in the automotive sector, for high data transfer rates in computer networks or for long-distance transmission across the Atlantic. In order to meet the increasingly stringent quality requirements resulting from ever larger data volumes and shorter transfer times and to achieve the required production quantities, the connectors and the optical fibers must be bonded in an automated process in the future.

Until now, the 2-component epoxy resin from EPO-TEK has been applied manually. A very complex and error prone process. To be able to apply the adhesive by hand using a syringe, it must be mixed and filled precisely in advance. The desired precision of both the mixing ratio and the application of the minimum amount of adhesive is simply not achievable in the manual process. In addition, due to the pre-mixed cartridges, high residual amounts of material are sometimes produced.

The tests at preeflow showed that the required quality standards are more than met when implementing the dosing process with the eco-DUO330 2-component dispenser. The volumetric dispenser was convincing in terms of repeatability, ease of service and, above all, process reliability. The fully automatic production line is currently being planned.