Continuous Condition Monitoring from Pfeiffer Vacuum

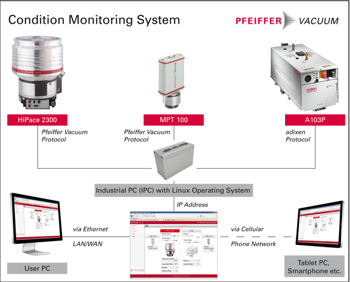

Pfeiffer Vacuum has developed a Condition Monitoring System (CMS) that affords optimum monitoring of the operating condition of vacuum pumps and vacuum gauges.

Pfeiffer Vacuum

Monitoring is especially advisable for systems that incorporate a large number of pumps or pumps that are difficult to access. In special applications, data transfer can be effected by means of fiber optics in order to bridge high voltage potentials, for example. Continuous condition monitoring of the pumps and vacuum gauges in a system prevents outages and helps to save costs.

The CMS can be employed with all products from the Pfeiffer Vacuum product portfolio that have the Pfeiffer Vacuum protocol or the adixen protocol available via an RS 485 interface. Together with the customer, definition is made of the relevant data that are to be read out and displayed via the CMS. An industrial PC, which functions as a Web server, consolidates the individual signals from the vacuum pumps and gauges and sends them to a specified IP address. This additionally means that the system is platform independent, as the Internet page is compatible with all popular browsers that support HTML 5. And it further assures that the CMS is independent of the operating system. The data can be transferred either over a company’s own Ethernet, the Internet or wirelessly.

Should the limits defined by the setup be exceeded, the change in operating condition is signaled graphically from green to yellow to red, in accordance with the traffic light principle. This represents a simple way of implementing monitoring for multiple systems, and thus various pumping station combinations.

Source: Pfeiffer Vacuum GmbH