Blackmer Extends XLW Series Sliding Vane Pump

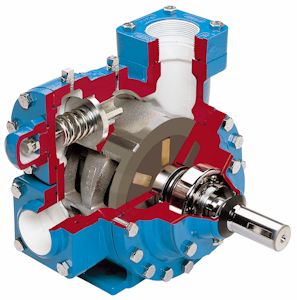

Blackmer is pleased to announce the availability of the XLW4A Model Sliding Vane Pump. This 4-inch pump is an extension of Blackmer’s XLW Series Sliding Vane Pump line, which was introduced in 1978.

Blackmer

XLW Series pumps have been designed to perform in the handling and transfer of a variety of abrasive liquids, including oxide primers, inks and paints, where wear-resistance is critical to pump operation. XLW Series pumps have also shown to be successful in applications such as vertical and horizontal bead mills, solvent recovery, tank-bottom recirculation, heat-treater supply, enhanced oil recovery, and crude- or hot-oil transfer.

As with all XLW Series pumps, the XLW4A model features hardened rotor and shaft, liner, end discs and vanes for long life and optimized wear-resistance. These hardened internal parts allow the pump to be used with liquids featuring suspended abrasive particles up to 250 microns in size and at a concentration up to 25%.

The XLW4A model can produce flow rates up to 190 gpm (719 L/min) at speeds to 350 rpm; handle viscosities to 20,000 SSU (4,250 cSt); operate at differential pressures to 150 psi (10.3 bar) and working pressures to 350 psi (24.1 bar); and handle temperatures up to 300ºF (149ºC).

Source: Blackmer