AxFlow Introduces Waukesha’s MDL Hygienic Positive Displacement Pump

AxFlow AB has added the new Waukesha MDL Series pump to its product portfolio.

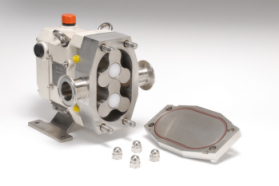

Waukesha MDL Series pump (Photo: AxFlow)

With nine models available giving capacities up to 124m³/hr and differential pressures of 10 bars, this new rotary lobe positive displacement pump has been developed for medium duty sanitary applications within the food, beverage and pharmaceutical industries.

Featuring two stainless steel triple lobe rotors the MDL Series pump provides gentle product handling characteristics, making it ideally suited to handling viscous, non-abrasive and sensitive fluids where low shear is of major importance. Being a lobe pump, it is easy to clean as there are few fluid cavities where bacteria can grow, so it is suitable for CIP and has been designed and engineered to conform to EHEDG certification for the European market.

AxFlow says that the MDL Series has been developed specifically to satisfy the many middle range duties and applications in the sanitary products and food processing industries that need the gentle action of a positive displacement pump, but do not justify the costs of high-end specification pumps. The MDL fills a much needed gap in the market without compromising on operating integrity and quality.

In developing the MDL Series WCB has drawn on the proven technologies within its product line in order to provide a pump that offers optimum performance and versatility. The four-way mounting gear case, including vertical alignment of ports, gives users greater design freedom when it comes to installation of the pump. The design also means that the pump is easy to disassemble/assemble for service and maintenance. This is further aided by the attention given to the design of the shaft, which utilises a unique rotor attachment that provides repeatable rotor positioning and solid torque transmission. Furthermore, the unique design of the gear box ensures that there is no cross-contamination of the lubricating oil into the product zone.

AxFlow is offering the MDL pump with an economical simple single mechanical seal as standard, but where required there is the option of a flushed double mechanical seal that can run dry indefinitely. The new pump is already in stock at AxFlow Systems’ European Distribution Centre, where it has the facilities to assemble units in under three days.

Source: AxFlow Group