Armstrong Fluid Technology Introduces A New Air-Cooled Chilled Water Plant Control System

Armstrong Fluid Technology has introduced a new Chiller Plant Automation System targeted at optimizing the performance of air-cooled chiller plants.

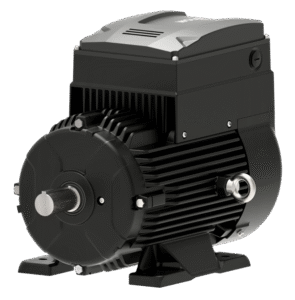

IPC 9511 Streamlines Building Operations and Lower Costs (Image: Armstrong Fluid Technology)

The IPC 9511 streamlines plant operations and can lower operating costs. Facility managers and engineers seeking an easy-to-use, comprehensive Plant Automation System will benefit from this fully field-configurable solution with automation features for constant speed and variable speed configurations.

The IPC 9511 brings a number of industry firsts to the market. Most noteworthy of these is the pre-configured serial communication setup options for most common chillers, VFDs, and Armstrong’s Design Envelope pumps. The same ease-of-use applies for field configuration of communications with the local building automation system (BAS).

Armstrong’s IPC 9511 offers another industry first with patent pending Sensorless pump speed control technology, allowing owners to save on the cost of remote differential pressure zone sensors and flow meters. The IPC 9511 on its own can provide both variable primary flow automation, and is also configurable for primary secondary plant configurations.

The IPC 9511 is fully internet and intranet capable and can support Armstrong’s ECO*PULSE Health Management System to provide local 24/7 automated plant diagnostics with analysis and cloud-based reporting capabilities.