Amarinth Delivers API 610 OH1 Pumps to Kanfa for the Second Karish FPSO Oil Train

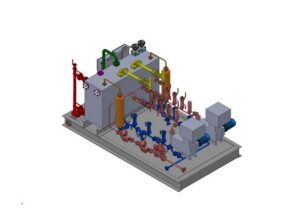

Amarinth API 610 OH1 pumps on bespoke skid ready for shipment to Kanfa (Image source: Amarinth Ltd.)

The addition of the second 700-tonne oil train for a new oil / condensate separation module for the FPSO operating in the Karish field in the eastern Mediterranean off Israel will increase the production capacity of this brownfield site by 75%. Kanfa will provide a fully assembled M10 topside module which will be transported to the Karish field for integration onto the FPSO.

Amarinth has supplied Kanfa with two API 610 pumps with a Plan 53B Seal Support system for the new oil train. The pumps, for ATEX Zone 2 operation, have been designed to the newest API 610 12th Edition and manufactured in stainless steel to Norsok specification. Due to space restrictions aboard the FPSO, a bespoke single footprint skid design was required which both pumps and the two Plan 53B Seal Support systems are all mounted on together.

The pumps were delivered on a very aggressive 30-week lead time to fit with the build schedule of the new M10 topside module. The pumps were witness tested by DNV at Amarinth’s test facility in the UK before being air-freighted to Dubai, UAE, where the new topside module is being constructed.

Oliver Brigginshaw, Managing Director of Amarinth, commented: “We are delighted to deliver this order to Kanfa, the first we have received from them. This is further testament to our proven agility in providing bespoke pumping solutions on very tight lead times to meet the challenges facing the world’s oil and gas industry.”

Source: Amarinth Ltd.