Allison Engineering: Flange Protectors Prevent Hazardous Pipe Corrosion

Protecting pipelines from the damaging effects of corrosion is an essential requirement for many offshore or onshore oil and gas installations, where if left unchecked can cause leakage, failure and in extreme cases, result in expensive shutdown.

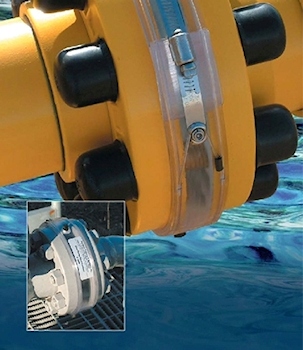

Kleerband Flange Protectors prevent pipe corrosion (Image: Allison Engineering)

Kleerband Flange Protectors, recently introduced by Allison Engineering are an innovative solution to the problem as they provide a quick and easy way to apply protection and prevent corrosion. The Flange Protectors offer benefits compared to traditional corrosion protection devices such as shrink sleeves, tapes and wax fillers.

For example, they are simple to install with a worm-gear connection, with no mess or special tools. They feature a positive loading relief valve vent and plug which ensures complete loading of flange cavities, whilst a transparent and flexible polyband allows for 360º uninterrupted inspection, without the need to remove the protector.

Kleerband protectors are designed to fit all DIN and ANSI flanges from ½” diameter up to 144” and are also available for non-standard sizes and Christmas-Tree applications off-shore. In addition to being used on oil and gas installations they are also ideal for protecting flange faces, studs, gaskets and ring joints on pipelines in chemical plants, refineries, oil fields, metering stations, water and waste water plants, pump stations and underground pipelines.

Source: Allison Engineering