Advanced DEF Drum Pumps for Enhanced Efficiency and Reliability

Advanced DEF Drum Pumps for Enhanced Efficiency and Reliability (Image source: Finish Thompson Inc.)

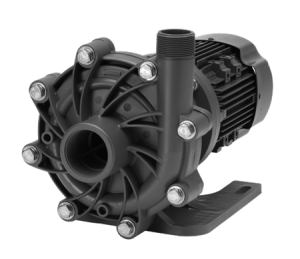

The PF Series features a high-performance sealless pump that ensures maximum uptime and seamless fluid transfer from small containers to 55-gallon drums and IBCs. Its unique double suction impeller delivers high flow rates and discharge pressure, allowing for quick filling of large DEF storage tanks. Additionally, the rugged design includes a heavy-walled polypropylene tube and a metal motor coupling, ensuring durability even in demanding transportation environments.

The SF Series represents the latest generation of sealless pumps, offering both high flow and high head options to cater to diverse application needs. The 40 mm tube diameter allows for compatibility with smaller bung openings, making the pump lighter and more compact without compromising performance. This series is available with a wide motor selection, including electric, air, and explosion-proof options, making it suitable for use in hazardous areas containing flammable vapors.

The EF Series is an ideal replacement for traditional hand pumps, featuring a leak-free sealless design that eliminates the fatigue and reliability issues associated with manual pumping. An integral strainer helps keep debris out, ensuring the purity of the DEF. For ultimate portability, the EF Series offers a lithium-ion battery motor option capable of pumping more than 13 55-gallon drums on a single charge. This series also includes built-in hose and cord clips, as well as a powered pump option for bucket and pail use.

Finish Thompson's drum pumps are not limited to drum use; they can be utilized in various container sizes, including barrels, totes, and IBCs. This adaptability, combined with their OEM approval for SCR systems, ensures a long life for these critical systems by maintaining DEF purity and preventing contamination.

Source: Finish Thompson Inc.