From Depths to New Heights: Revolutionizing Wastewater Pumping with Above-Ground Technology

From Depths to New Heights: Revolutionizing Wastewater Pumping with Above-Ground Technology (Image source: Smith & Loveless Inc.)

Benefits and advantages of above-ground pumping stations

Relocating pumps above ground safeguards the pumps’ mechanical and electrical components as well as the workers who handle them. This simplifies maintenance by making the equipment more accessible and eliminates the need for workers to enter dangerous, confined spaces, thus improving safety.

It also reduces wear and tear on equipment and minimizes breakdowns. By dramatically improving reliability, pump efficiency and longevity, the increasing adoption of above ground systems aligns with sustainability goals by eliminating the costly problems of frequent stocking, replacement and disposal of submersible pumps. Above-ground pump stations offer a decades-long lifespan, significantly outperforming the few years typical of submersible pumps. The longer service life and easier maintenance add up to a significantly lower total cost of ownership.

Let us look more closely at the key advantages:

Ease of maintenance and safety – Ensuring the reliability and performance of pump station operations necessitates regular maintenance, underscoring the critical need for pump operators to conduct these tasks in a safe and efficient manner. There is also an overall desire in the industry for less contact with hazardous materials, including raw sewage, drugs, medicines, debris, and needles, making wastewater maintenance tasks safer in the long term.

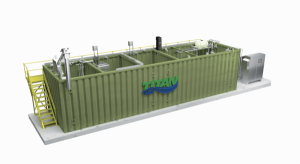

With above-ground systems, the pumps, control panel, equipment, and valving can all be contained within an aesthetically pleasing building or enclosure. A single staff person working alone can simply drive or walk up to the structure to check motors and valves, and readouts can be easily taken. This simple fact alone helps facilitate operations and maintenance (O&M) budgets, because multiple staff are not required for routine checks. In addition, staff can dramatically reduce contact with raw sewage, and work in a clean environment.

By contrast, conventional submersible lift station designs present significant safety hazards, complicating maintenance procedures. Submersible lift stations employ sealed pumps that operate while fully submerged in the wet well. These pumps are periodically lifted to the surface for maintenance and reinstallation using guide rails and a hoist. While submersible lift stations require only the wet well to house the pumps, most still require a separate valve vault, usually placed a few feet away from the wet well. The control panel is often located above ground.

Lift stations that require access to the wet wells and any associated valve vaults pose significant safety challenges because operators entering these spaces to perform routine maintenance or emergency repairs are exposed to risks like toxic gasses and contact with sewage. These spaces will often be classified in accordance with OSHA guidelines as confined spaces by municipal utilities and industrial end-users. Confined space entry requirements require strict and costly protocols, including permitting, multiple personnel (2-3), proper ventilation, gas monitoring, harnesses, and protective gear, along with thorough training for adherence to OSHA standards and other requirements.

These requirements drive up maintenance fees, which is a burden in all jurisdictions, but is especially challenging in rural areas where there may be one maintenance worker on staff, who would have to work with the local fire department to meet the confined space requirements. The onus would be on the town to allocate the necessary budget.

Energy efficiency improvements – New application-specific designs are being developed to increase efficiency for above-grade pumps. Using more modern technology, including variable frequency drives (VFDs), these pumps help meet energy efficiency goals even more.

Sustainability – Submersible pumps in water are submerged in a hazardous environment, and they have a life span of 5-10 years, resulting in an extremely high need for remanufacturing and rebuilding that increases overall emissions for the equipment. In addition to the considerable manufacturing costs, disposal is an issue, since landfills often do not want to accept the used pumps – and there is a very limited market for scrap. Bearing the long-term costs of manufacturing equipment over and over has become a significant burden and is not in line with current sustainability policies. Municipalities and Sewer Districts are also encouraged by submersible pump suppliers to stock backups and maintain a supply of backup pumps in the (very likely) event they have a failure and need to change out a pump.

Compare that to above-ground pumps, which can last 20-30 years because they do not come in contact with the sewage, and the chance of catastrophic failure is low. Above-ground equipment lasts 3-4 times longer than submersible pumps, driving sustainability far higher. Compared to submersible pumps that are usually manufactured overseas, above-ground pump stations have reduced shipping costs, which also improves the sustainability equation.

It should be noted that the above-ground concept does have several limitations. Firstly, above-ground pumps are limited by physics on how high they can pull wastewater. The limiting factor is typically 20 feet, depending on elevation.

Another factor is availability of options. At present, there are far more types of submersible pumps available. With their larger footprint in the global market, submersible pump options are available for a larger variety of smaller and larger pump sizes, and wet well depths.

Trends affecting move toward above-grade pumping stations

Several regulatory, business, and environmental trends are affecting the move towards above-ground pumping systems. Perhaps one of the largest drivers is staff limitations. With the generational shift occurring in the labor force, fewer people are available for operator jobs. This should make above-ground systems more appealing to municipalities and sewer districts because the elimination of confined space entry when performing routine maintenance also eliminates the additional staff, training, and associated safety gear.

The market for above-grade pumping stations is also positively affected by the Build America, Buy America (BABA) Act, a law that requires the use of US-made materials and products for federally funded infrastructure projects. Most above-ground pumps are manufactured domestically, and the American made concept is gaining traction with many funding sources. In addition to supporting American enterprises, purchase of above-ground equipment avoids the sometimes-serious supply chain issues associated with shipping and transportation of equipment made in Asia or elsewhere.

Aesthetics is another issue that is being considered as more attention is being paid to the concept of environmental justice, including ensuring infrastructure fits into a neighborhood setting. Above-ground equipment can be built within an attractive structure that hides a sewer pump station.

On the ground examples of benefits of above-grade pumps over traditional submersibles

One example comparing maintenance and repair costs of above-ground well-mounted pump stations versus submersible pumps is a comprehensive 12-year side-by-side study conducted for the Unified Government of Wyandotte County and Kansas City, Kansas. The published study1 demonstrated the life-cycle cost advantages of above-ground lift stations compared to their submersible pump counterparts. Utilizing asset management software, the study scrupulously recorded all maintenance and repair expenses for 53 duplex pump stations within Wyandotte County’s wastewater collection system. This study measured and compared labor hours and costs, outside contractor expense, parts costs and total expenditures for these stations over the 12-year period.

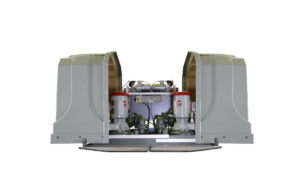

They used the information to conduct a comprehensive analysis of the operational and maintenance costs of 21 submersible pump stations and 32 above-ground EVERLAST wet Well Mounted Pump Stations (WWMPS) packaged systems from Smith & Loveless, all functioning under similar conditions and applications. These systems feature all pumps, piping, valves and controls installed outside of the wet well, at grade level, making operation and maintenance simpler, safer and more economical.

The findings revealed that the above ground systems yielded nearly 56 percent in total cost savings, translating to an average annual saving of more than $2,700 per station, for a total savings of almost $400,000. In addition, the study revealed that not one pump of the 32 above-ground pump stations required replacement, whereas 40 pumps needed replacement in the county’s 21 submersible stations.

Another example is Fremont County, Idaho2, near Yellowstone National Park, which had significant system-wide operation and maintenance challenges originating from 45 lift stations within the collection system. The stations include underground dry-pit lift stations, submersible lift stations, above-grade vacuum-primed lift stations, and small grinder stations. The sprawling distance of the network complicated preventative O&M and repairs, as periodic inspection of every station was not realistic. The number of County Public Works technicians typically ranges between two and three to cover the entire collection system network.

The large variety of lift station types, system configurations, and pump brands that had been installed made it difficult to apply common troubleshooting practices or anticipate problems. The County also had to maintain a large inventory of spare parts, not to mention O&M knowledge from the various lift station/ pump manufacturers. The stations were also running into issues with manufacturers that had gone out of business or had stopped producing parts for the pumping systems.

Looking to reduce its parts inventory management, improve operating efficiency, and lower operating costs, Fremont County decided to standardize on three pumping systems classifications depending on the application. They found that the packaged wet well mounted above-ground pump station design and prepurchase process enabled them to conduct all lift station installations for the majority of the lift stations with existing staff. The process also improved staff knowledge of equipment, lowered overall O&M time and costs, and reduced spare parts inventory. In addition to improving operational efficiency, the selection of the packaged above-ground equipment resulted in tremendous savings to the ultimate bottom-line. Total annual maintenance costs for the above-ground station was less than half that of submersible pumps.

A further example comes from the Klein Independent School District, near Houston, TX, with 20 submersible wastewater lift stations that required costly specialized maintenance and service protocols to meet OSHA and other Class1 Div 1 standards, like hoists, safety harnesses, gas monitoring equipment and a vac truck. This made it impossible for district staff to handle repairs internally. “Unless it winds up being an electrical issue above ground, which is very rare, we are calling a contractor 95 percent of the time,” explains Steve Cox, the district’s Maintenance Supervisor for Mechanical, Electrical and Plumbing.

Requiring none of the tools or safety protocols associated with submersibles, the pumps feature pre-engineered standard designs that promote superior operator knowledge and common troubleshooting practices. One single full-time lift station technician can operate and maintain all of the district’s lift stations. The technician easily and safely inspects each of the district’s above-grade stations by simply walking up and opening the lightweight enclosure.

“With the S&L (above-ground) stations, we can do just about everything no problem with just one guy,” Cox said. “Problems are not a very common occurrence. The S&L stations run very well.” In addition to significantly reducing labor and contractor costs, there have been zero repairs or replacements by outside contractors to S&L pumps over the last decade.

One final example comes from the Royal Cornwall Hospital in Truro, United Kingdom. “Our original submersible pump stations were no longer maintainable by our in-house staff,” said Leslie Dey, Estates Officer for the hospital, “Keeping up with the training to send anyone down there would have been a massive cost.” Dey was able to take back ownership of his lift station equipment and dramatically reduce operations costs by converting from submersible pumps to S&L’s EVERLAST Wet Well Mounted Pump Station.

“The beauty of the equipment all being above-ground is that all of our guys can access them fairly easily,” Dey said. “Everything is inside that one neat little package that they can all maintain.”

The EVERLAST systems are available in either tip-up or sliding enclosures with a variety of base sizes, handling up to 1,300 gallons per minute. Models feature either relay logic controls or QUICKSMART controls, which give operators the ability to monitor and adjust all pump station functions. The easy to use, intuitive layout makes control modifications, screen navigation and viewing of pump station status easy, with screen function buttons and a status bar accessible from every screen. Controls include PLC station control, alarm management, wet well level simulation, prime mode selection, help and troubleshooting info, graphical pump notifications, with instructions in both English and Spanish.

Additional available QUICKSMART features include a new maintenance log feature, which displays periodic recommended operation/maintenance instructions and makes lubrication suggestions based on actual pump run times, as well as an improved help/troubleshooting support and a new I/O Status screen that displays both digital and analog I/O status.

Above-grade pump stations fit in with a more forward-thinking approach

In the past, the submersible pump has been a typical choice for engineers working in this market, and younger engineers had typically not been exposed to newer technologies. But now, many younger environmental engineers and municipal utility professionals are gravitating to above-ground pump technology, looking for ways to improve operations. The increasingly massive amounts of wipes and debris are overwhelming municipal collection systems and pumps that were simply not designed to handle it.

The advantage of above-ground pumps with uniquely designed mono-port impellers can handle the debris and purposely pass it to the treatment plant for proper removal. Now, the limited staff is not faced with the difficult task of continually pulling and replacing due to clogs and failures, and the hazards of accessing confined spaces.

By: Rich MacGregor, Technical Writer

References

1 White Paper: Wet Well Mounted Pump Stations vs Submersibles, https://www.smithandloveless.com/white-paper-wet-well-mounted-pump-stations-vs-submersibles, retrieved 1/8/25.

2 Self-Performed Lift Station Assessment and Replacement - Managing Assets Through Tiered Standardization, Wastewater Digest, https://img.wwdmag.com/files/base/ebm/wwdmag/document/2022/06/1655328307267-wp_fremont_county_tiered_standardization.pdf?dl=1655328307267-wp_fremont_county_tiered_standardization.pdf, retrieved 1/8/25.

Source: Smith & Loveless Inc.