ARI USA Ensures Reliable and Efficient Steam & Condensate Management

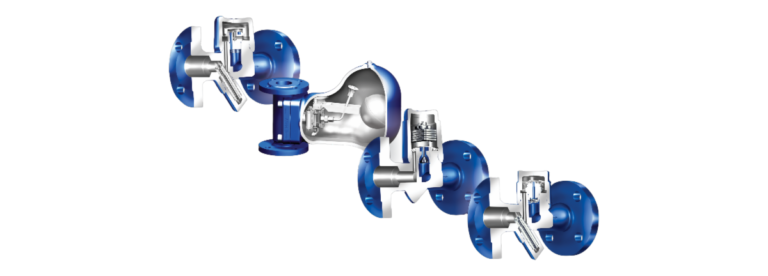

CONA Steam Traps (Image source: ARI-Armaturen)

With extensive product selection, vast inventory, and expert consulting services, ARI delivers comprehensive, end-to-end steam & condensate solutions for uninterrupted performance, reduced energy consumption, and optimized operations. This can be especially critical for industries in power, healthcare, chemical processing, and food production - sectors where downtime and inefficiency are not an option.

The broad portfolio of CONA steam traps ensures the perfect steam trap for every application. The CONA S mechanical ball float trap is a versatile solution that adapts to a wide variety of operating conditions and applications, engineered to handle major fluctuations in pressure and condensate load and instant discharge with no temperature loss.

The CONA B bimetallic thermostatic steam trap is specifically designed to handle condensate that is significantly below the boiling point of the steam. The CONA M diaphragm capsule thermostatic steam trap is designed for applications with cold startups. For systems requiring continuous operation, the CONA TD thermodynamic disc steam trap is a small, practical solution, insensitive to ambient conditions for the discharge of condensate close to saturation temperature.

ARI’s steam traps are designed for maximum adaptability, so the same trapping technologies are also available in universal trap configurations. The CONA Universal product line enables streamlined installation and quick, hassle-free replacement or maintenance that does not disturb existing pipe work. Additionally, the CONA All-in-One Compact system offers an innovative solution for condensate discharge. This patented multi-valving system integrates a steam trap, stop valve, strainer, check valve, and drain valve into a single unit, reducing pipe connections by up to 80%.

Defective steam traps can lead to significant steam losses, higher generation costs, operational safety risks, and increased carbon emissions. The impactful way steam traps can affect an entire system is why ARI-Armaturen offers on-site steam system surveys with trained experts, ensuring maximum system stability and efficiency.

When steam systems fail, mission-critical operations turn to ARI-USA for superior products, a vast inventory, and engineering expertise to quickly diagnose and resolve issues. Renowned for rapid response, ARI-USA maintains high customer loyalty with quick turnaround times—with most in-stock items shipped within 24-48 hours. This reliability is essential for preventing costly downtime in critical applications. Supported by a strong, family-oriented company culture and exceptional employee retention, ARI-USA consistently delivers quality and dependability.