Amarinth Enhances ADNOC Gas Operations with Remote Bearing Temperature Monitoring and Flush System

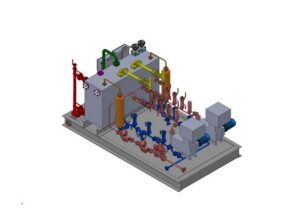

Amarinth engineer testing an external flush panel (Image source: Amarinth Ltd.)

ADNOC Gas, a subsidiary of ADNOC, manages over 3,000 km of pipeline networks and 26 processing trains. The company supplies around 60% of the UAE’s natural gas requirements and serves customers in more than 20 countries.

The project involved upgrading four API 610 VS4 vertical pumps with remote bearing temperature monitoring and flush systems. These pumps, originally supplied to ADNOC Gas by Amarinth over a decade ago, have been operating reliably. However, recent changes to process conditions introduced a heavier particulate loading in the fluid, which posed a challenge to the line shaft bearings.

Amarinth's innovative solution addressed the risk of clogging and lubrication starvation of the bearings that can lead to overheating and pump failure. The modification integrated advanced Resistance Temperature Detectors (RTDs) to monitor bearing temperatures in real time. To endure the highly corrosive effects of hydrogen sulphide (H₂S) in the process fluid, the probes were encased in a stainless-steel sheathing.

The real time data from these temperature probes is transmitted through a complex array, emerging through the pump’s baseplate, to a centralised dashboard, enabling engineers to monitor and control operations remotely. If bearing temperatures exceed a critical threshold, the system automatically shuts down the pump and initiates a flushing process, preventing damage and minimising downtime.

This innovative approach delivers significant operational benefits, including:

- Enhanced reliability and safety through real-time monitoring and automated shutdowns.

- Reduced spare parts requirements and maintenance downtime.

- Prolonged pump life by preventing bearing damage before it occurs.

Amarinth successfully designed and tested the refurbished pumps in just 20 weeks, demonstrating its agility in delivering innovative solutions. To further support ADNOC Gas, Amarinth also offered an optional installation service. ADNOC Gas has since launched these upgraded pumps as a pilot project, assessing the feasibility of implementing this modification across its fleet of VS4 pumps at multiple sites.

Beyond this project, Amarinth provides its specialised expertise in modifying VS4 vertical pumps for bearing temperature monitoring and flush systems not only for its own pumps but also for non-Amarinth VS4 pumps. These enhancements can improve functionality, boost reliability, and extend the operational lifespan of all VS4 vertical pumps within an organisation’s infrastructure.

Oliver Brigginshaw, Managing Director of Amarinth, commented: "Once again, we are delighted to assist ADNOC, a long-standing customer, in upgrading their existing pumps. This remote bearing temperature monitoring and flush system showcases our commitment to delivering cost-effective, tailored solutions that meet our customers’ evolving needs. By enhancing their operations without the disruption of installing new pumps, we’ve reinforced the trust ADNOC places in us as their partner of choice."

Source: Amarinth Ltd.