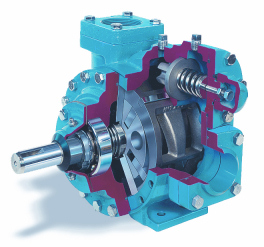

XL Series Sliding Vane Pumps Offer High-Level Performance In Lube-Plant Applications

Blackmer announces its XL Series sliding vane pumps are ideal for process, filling and transfer applications in lube oil plants. Utilizing Blackmer’s unique sliding vane design, XL pumps offer lube-plant operators the best-in-class combined characteristics of sustained high-level performance, energy efficiency, trouble-free operation and low maintenance cost.

Blackmer

XL pumps are constructed of ductile iron that will withstand sudden thermal shock and stress well beyond the capabilities of cast iron pumps. All models are fitted with replaceable casing liners and end discs that allow easy rebuilding of the pump without the need to remove the pump from the piping. The XL models are available in 1.25-, 1.5-, 2-, 3- and 4-inch port sizes with capacities from 5 to 345 gpm (19 to 1,305 lpm). The 1.25- and 1.5-inch models have NPT-tapped ports and are capable of running at motor speeds up to 1,750 rpm. The 2-, 3- and 4-inch models have flanged ports.

Standard elastomers include FKM O-rings with optional Buna-N or PTFE elastomers also available. A wide variety of mechanical seal components and vane materials are optional. Mounting options include base-mounting with helical gear reducers for all sizes or an integral bracket for direct mounting to a NEMA C-face motor for the XL1.25 and XL1.5 models.

Source: Blackmer