Wilo Circulators for Packaged Sets

To meet the growing demand for packaged circulating pumping solutions, Pressmain Pressurisation Company is increasingly relying on the diverse range of ...

circulators supplied by Wilo Salmson Pumps Ltd.

Time-saving exercises aren't new. They've been a part of business since Henry T Ford opened his first factory almost 100 years ago. By introducing the ethos of mass production, the famous industrialist cut production times of his Model T from 14 hours to just over an hour and half. For Henry, time meant money.

Today, building services contractors are following Henry's lead by favouring packaged pumping solutions that cut installation times and reduce the need for on-site commissioning engineers. The plug-in-and-go culture is a response to the spiralling costs associated with on-site project work and as a viable method of reducing overall costs.

"Site time is expensive," says Gerry Cooke, Managing Director of Pressmain Pressurisation Company, a Manchester-based company specialising in the design and manufacture of packaged pump equipment. "Because site costs are so excessive, people are looking for packaged sets that are quicker to install and more efficient to commission. The industry is leaning towards packaged units because you can deliver the unit down and connect it up. It's that simple."

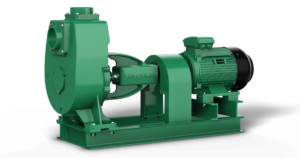

Pressmain supplies fully packaged pumping systems for multi-million pound development projects, including some of the latest hospitals and hotels. A key element of Pressmain's all-in-one solution is Wilo Salmson's twin-head, glanded pumps.

"You've got to get the right pump with the right system," Gerry says. That selection, he explains, often depends on the range solutions offered by the pump manufacturer. "Wilo's circulators are very good. They're efficient and cost effective. Other manufacturers make similar pumps, but don't provide such a wide selection. Wilo can provide single, twin heads, inverter-controlled systems - the list goes on. Having someone who can offer a full range is important because we can get involved in a wider range of projects."

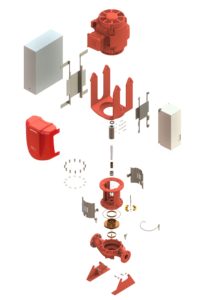

The Wilo-DPn flange-ended inline pump is one of a number of high-performance circulators developed by Wilo to cater for the heating, air conditioning and mechanical services market. It consists of two monobloc, single-stage, centrifugal pumps that can operate independently or in unison. Also featuring a flange-mounted motor that reduces excessive vibration, the unit ensures high levels of reliability due to a common motor/pump shaft with shaft sleeve and pressure-compensated bearings.

The pump, Gerry explains, is an integral component of Pressmain's packaged circulating systems, which include a recent bespoke solution for Airdale International Air Conditioning. The one-off pre-assembled set will act as a main circulator for a dual water system. It features a Wilo-DPn unit - with both pumps rated at 15Kw - mounted on a base that includes all the necessary pipework, filters, isolating valves, pressure vessels and control panels.

"The system couldn't work without the Wilo pumps," Gerry says. "They're excellent. They've never let us down and they're extremely efficient. Good efficiency speaks for itself - it's what people are looking for and, commercially speaking, Wilo pumps are the best around."

For further information, visit the Wilo Salmson website at:

Source: WILO SE