Wilden Pumps Deliver Effective Transfer of Carbon Slurry in Pharmaceutical Applications

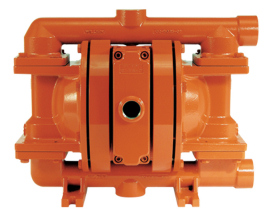

Wilden, the worldwide leader in air-operated double-diaphragm pump technology announced that its Advanced Series PX200 stainless-steel pumps provide pharmaceutical systems developers with the most effective air-operated double-diaphragm pump solution for the transfer of carbon slurry.

Wilden Pump and Engineering, USA

The Advanced Series pumps feature Wilden’s patent-pending Pro-Flo X air distribution system (ADS), which offers operational flexibility in carbon slurry transfer applications. This flexibility is accomplished by the state-of-the-art Efficiency Management System (EMS), which optimizes the Pro-Flo X ADS for the actual operation parameters regardless of the application demands or pump size. The EMS allows the operator to use an integrated control dial to select the efficiency point and flow rate that best suits the application.

Advanced Series PX200 air-operated double-diaphragm pumps are powered by natural gas and have been tested and certified by CSA International for use in applications where compressed natural gas is the energy source and the driving force of the pump. The PX200 pumps come with a blue serial number tag for easy identification in the field and also include a caution sticker that details specific safety information, and the appropriate CSA certification logos.

About Wilden

Jim Wilden, founder of Wilden Pump and Engineering Co., revolutionized the pumping industry when he invented the air-operated double-diaphragm pump in 1955. Since then, Wilden has created a line of distinctive pumps that have proven to be trustworthy solutions to pumping applications in a wide variety of industries. Wilden - headquartered in Grand Terrace, California, USA - is a member of Dover Corporation’s Pump Solutions Group (PSG).

Source: Wilden