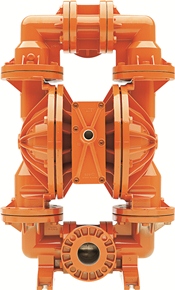

Wilden Advanced Series Provide Energy Efficient Pump Alternative in Paint & Coatings Applications

Wilden is pleased to announce that its Advanced Series Metal Air-Operated Double-Diaphragm Pump technology features the operational advantages necessary to overcome the challenges in the ever-evolving, oftentimes difficult operating conditions found in Paint & Coatings manufacture.

Wilden

As significant changes have occurred over the years to the materials used, paint-and-coatings production has become more of a refined science. That means manufacturers must utilize robust equipment that offers the highest degree of performance in terms of reliability, product-loss prevention, environmental protection and energy efficiency, while retaining the versatility required to handle a wide variety of components, all of which possess unique handling characteristics. Wilden’s Advanced Series pumps possess the versatility that allows them to be used at every stage of the paint-and-coatings production process, from raw-ingredient transfer to mixing, batching and filling. The Advanced pumps are ideal in all of these applications because most require operating pressures of less than 125 psi, they offer shear-sensitive operation, they can handle high-viscosity fluids, they have a leak-free bolted configuration and they can overcome the dead-heading that can occur during filling operations, which motor-driven pumps can’t complete effectively.

Advanced Series pumps also benefit from Wilden’s Pro-Flo X Air Distribution System (ADS), which delivers cutting-edge operational flexibility through its patented Efficiency Management System (EMS). The EMS allows the user to optimize the ADS for any application demands, through the use of a control dial that enables the flow rate that best suits the specific application to be manually selected. Advanced pumps are also available with full-stroke PTFE diaphragms that deliver increased product displacement per stroke, resulting in improved performance and efficiency.

Source: Wilden