Wilden Advanced and Original X Series Pumps Earn ATEX Certification For Use In Explosive Atmospheres

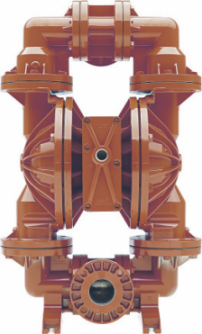

Wilden announced that its groundable Advanced and Original X Series Metal and Plastic air-operated double-diaphragm pumps comply with the ATEX 95 directive for explosive atmospheres.

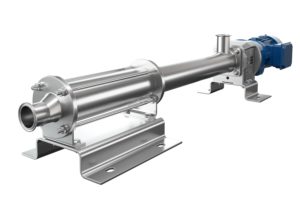

Wilden PX1500

The ATEX directive consists of two European Union directives that describe what equipment is allowed in an explosive atmosphere. Realizing that safety in potentially explosive areas can only be guaranteed by a close and effective working relationship amongst all parties, Wilden has taken responsibility for its pumps’ compliance with the necessary ATEX directives. Wilden’s metallic X Series pumps comply with ATEX 94/9/EC Group I, category M2 and Group II, category 2, zones G and D. Wilden’s plastic X Series pumps comply with ATEX 94/9/EC Group II, category 2, zone G.

Wilden also offers ATEX Retrofit Kits for its metal and plastic pumps that utilize the Accu-Flo, Turbo-Flo, Pro-Flo and Pro-Flo V air-distribution systems. These retrofit kits feature parts that are constructed of electrically and statically dissipative materials, with a wide variety of appropriate elastomer options. All of the parts feature a special ATEX marking that indicates the suitable ATEX categories where the pump can be installed.

About Wilden

Jim Wilden, founder of Wilden Pump and Engineering Co., revolutionized the pumping industry when he invented the air-operated double-diaphragm pump in 1955. Since then, Wilden has created a line of distinctive pumps that have proven to be trustworthy solutions to pumping applications in a wide variety of industries. Wilden—headquartered in Grand Terrace, California, USA—is a member of Dover Corporation’s Pump Solutions Group (PSG).

Source: Wilden