Why Ball Checks Often Fail as Foot Valves

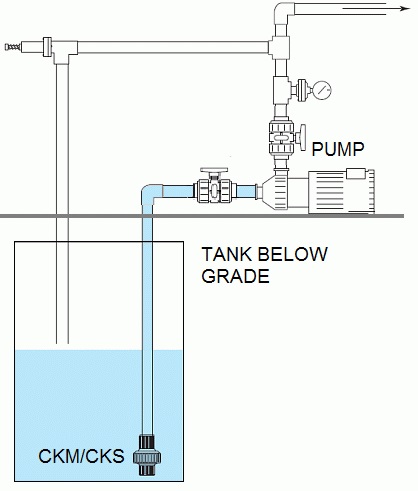

Notice how the liquid in the pipeline goes all the way to the pump intake. That's how a bubble-tight, normally-closed foot valve maintains prime to the pump. (Image source: Plast-O-Matic Valves, Inc.)

The problem is, not all foot valves are bubble-tight and normally-closed. Without a complete and perfect seal, the liquid in the pipeline will drop to the level of the tank, just like a soda straw.

The worst offenders are ball checks that double as foot valves. Ball checks require a few PSI of reverse pressure to actually close. So that's fine if the valve is new and head pressure is sufficient. But after repeated use the ball will be misshapen or worn, and generally will not affect a bubble tight seal. Leaking slowly, it's only a matter of time before the liquid level in the pipe equalizes the liquid level in the tank. Once that precious prime is lost, it can put significant wear and tear on the pump.

The Plast-O-Matic Series CKM relies on a patented diaphragm rather than a moving ball; it was designed specifically to beat this common problem. The CKM seals bubble tight automatically, regardless of head pressure. For larger pipe sizes, Series CKS uses a Teflon encapsulated spring to ensure the same automatic closure.

Although the patented CKM or CKS may cost a bit more than a mass-produced ball check, their superior design guarantees prime every time. In the long run, a few dollars for a more effective valve cost a lot less than a new pump and related downtime.

Source: Plast-O-Matic Valves, Inc.