Vesconite Bearings: 5000-Unit Blanket Order in Place

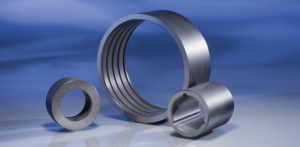

Some of the Vesconite Hilube wear rings that Vesconite Bearings produces (Image source: Vesconite Bearings)

The order, which covers a one-year-period, allows the manufacturer to request low-friction Vesconite Hilube polymer wear rings for 10 of its vertical-turbine-pump models. These have already been produced, and are simply ordered as required, and then invoiced and dispatched.

Vesconite Bearings technical sales representative Charlie Simpson notes that the company ordered its first Vesconite Hilube wear rings in 2015 and, after testing, started ordering larger quantities from 2017. In a March 2019 visit to the pump manufacturer, fixed volume requirements and pricing were finalised and these were included in the blanket order.

“The company is happy with the performance of the Vesconite Hilube wear rings,” says Simpson. “It sees the value of using the product and has switched all of its wear rings to Vesconite Hilube ones in all of its own-brand vertical-turbine pumps.”

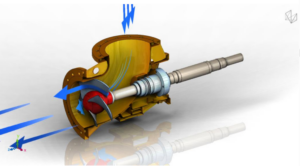

The manufacturer supplies the central and south-eastern USA with pumps for the municipal, industrial, fire and flood-control industries. Vesconite Hilube wear rings are valued because they allow for exceptionally close clearances to ensure greater pump efficiencies and save energy costs. They are also impeller friendly, and will act as a mechanical fuse - a sacrificial part which does not damage impellers, unlike bronze and stainless steel wear rings.

Wear rings from Vesconite Hilube are suitable for use with mildly acidic or basic liquids. Being hard wearing, they are suitable for use in applications where some debris is present.

Source: Vesconite Bearings