Vertical Sulphur Pumps Designed for the Oil and Gas Industry

Amarinth has invested over £1M designing a reliable low-maintenance range of API 610 VS4 vertical sulphur pumps for the oil and gas industry.

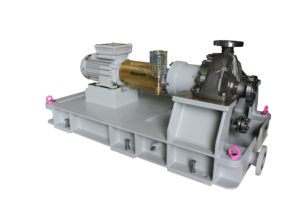

Amarinth API 610 VS4 Vertical Sulphur Pump (Image: Amarinth)

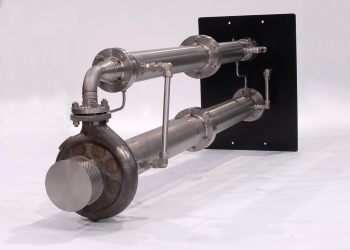

Elemental (pure) sulphur is a valuable by-product recovered during the refinement of oil and gas. Sulphur is extracted and transported around the processing plant in liquid form at a temperature of some 140C. However, sulphur only remains in its liquid state and therefore suitable for pumping within a narrow temperature band of approximately ±20C. At lower temperatures the liquid will start to revert to a solid and at higher temperatures its viscosity increases due to the formation of polymers, all of which creates unique challenges for the pumps.

Amarinth has drawn on its extensive expertise in designing bespoke pumping solutions for the oil and gas industry and applied this knowledge to produce an API 610 VS4 vertical pump that meets the requirements for pumping molten sulphur reliably. The company first undertook a detailed study of existing sulphur pumps (usually simple adaptions of existing designs) and how they were used and maintained to determine where issues occurred. Users reported high incidents of bearing failures, shaft problems and having to run significantly shorter maintenance periods to try and minimize failures, all of which resulted in increased downtime for plants.

To deliver a robust, reliable and easily maintainable pump, Amarinth then embarked on an extensive design and test study, resulting in a pump which comprises:

- A new arrangement for the shaft bearings and lubrication film which reduces the previous bearing and shaft issues operators had reported.

- Redesigned jacket to maintain the temperature of the molten sulphur and hence its viscosity, reducing the solidification of the sulphur around the pump particularly when it’s lifted for maintenance.

- New design of impeller optimised for best efficiency for molten sulphur.

- Amarinth’s proven modular column design that enables the rapid production of bespoke pump lengths and greatly simplifies maintenance and removal of the pump.

- Improved access so that regular maintenance can be completed quickly and with less disruption to the associated pipework and plant.

Following Amarinth’s investment of over £1M and years of research and design, oil and gas operators can finally acquire a cost-effective, efficient and reliable API 610 VS4 vertical sulphur pump designed specifically for transporting molten sulphur from point of extraction to ongoing processing.

Oliver Brigginshaw, Managing Director of Amarinth, commented: “We are delighted to offer these sulphur pumps, designed to meet the exacting needs of the oil and gas industry, in our extensive range of API 610 pumps. These sulphur pumps are the culmination of many years research and development by our team of dedicated engineers and we have pioneered a number of new technologies in their design which we look forward to applying in future applications.”

Source: Amarinth Ltd.