Varna Products Works with Cummins Power Generation on Blackstart Prelube

Varna Products is working with Cummins Power Generation to provide Turnkey DC Blackstart Prelube Systems for some QSK60L and QSV91L critical power generator sets.

Varna Prelube Pumps Minimize Engine Wear at Cranking and Help Ensure Generators Start.

The highest engine wear rate occurs during startup. The longer the period between engine starts, the more engine damage that occurs. While it is not possible to eliminate all engine wear, it is possible to minimize the extra wear at startup. A prelube pump can be used to pressurize the bearings and fill any oil galleries prior to cranking the engine. As engine cranking begins, the main lubrication pump can immediately supply oil to all critical lubrication points because the oil lines and galleries are already full of oil. The prelube pump has prefilled filled these areas prior to cranking.

On large stationary Natural Gas engines used in the non-emergency standby market, it is important to pre-lube moving parts prior to startup. These engines will stand idle for long periods of time between startups. It is necessary to protect parts from premature wear by reestablishing the oil film in between bearing surfaces prior to startup. When utility is not available due to a power outage, another means of carrying out the pre-lube process must put in place. Pre-lube can be accomplished using various power sources (i.e. air motors, hydraulic reservoirs)which can be expensive and complex, but a DC powered Pre-lube pump is easy to install and does not rely on separate powered sources other than the one the engine already uses for motor starting.

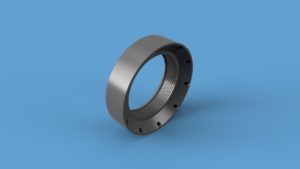

The Turnkey DC Blackstart Prelube Systems utilize’ s Varna’s Model CF15, 15 gpm max prelube pump with built-in check valve and pressure regulator direct coupled to 24VDC motor along with a custom-designed turnkey control system which is a back-up to the main AC driven prelube system.

Source: VARNA Products