US Army Fights “Energy Guzzlers”

"Energy saving" – the careful use of energy and the targeted reduction of its consumption – the US Army attaches great importance to this topic, also and especially on an international level. Since 2007, a clear strategy has been followed to set a good example regarding the protection of resources.

Wilo

According to the current "five-year plan", the US Military is to consume 3% less electricity, water and energy every year by 2015 and is thus to considerably reduce the CO2 emissions of their many bases worldwide. A big German-American project between the garrison of the US Army in Baumholder (Rhineland-Palatinate) and the pump specialist WILO SE showed which impressive potentials in electricity saving and climate protection are possible if many old pumps are replaced by most modern pump technology.

The garrison has a total population of around 13,700 people, 4,300 of which are soldiers. It includes several buildings consisting of a military area with headquarters, kitchens, hospitals and administrative buildings; a residential area with barracks and multi-family houses as well as civil utility buildings like schools, kindergartens, etc. The total energy demand is at 100 mio. kWh per year which causes costs of around 12.5 mio. Euros. The annual power consumption is at around 33 mio. kWh, electricity costs amount to approximately 3.3 mio. Euros.

In the context of comprehensive energy and water saving measures, the site has been optimised in ecological terms for many years. Particularly high electricity saving effects are expected from a project which started in 2008: around 2,400 uncontrolled heating and secondary hot water pumps of different sizes and construction types are replaced by high-efficiency pumps or electronically controlled glanded pumps in district heating and larger heating circuits.

When replacing pumps for the heat distribution in the buildings themselves, mainly electricity-saving high-efficiency pumps of the "Wilo-Stratos" and "Wilo-Stratos ECO" ranges are used. They are installed instead of existing uncontrolled glandless pumps or of outdated controlled models.

High-efficiency pumps for heating, air-conditioning and secondary hot water circulation have particularly electricity-saving EC motors and offer thus a doubling of the efficiency compared to electronically controlled pumps with conventional drive concepts. Due to the automatic adjustment of the pump output to the alternating operating states of the heating system, electricity costs are also considerably reduced compared to uncontrolled standard pumps. Especially in the partial load operation, which makes up close to 98 % of the operating time of a heating pump, a clear reduction of power consumption can be achieved compared to an uncontrolled pump.

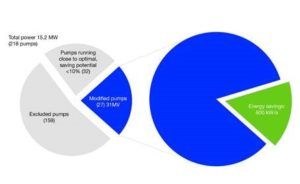

These outdated pumps have a considerable power consumption and therefore cause high electricity costs. Replacing these pumps by economical models of the latest technology can result in a reduction of consumption and also of costs by up to 90% and it even pays off if the old pumps still work. This is why managers of the garrison and members of the Wilo staff developed a replacement strategy. In a first step, the existing pump equipment was analysed. Then, Wilo delivered detailed calculations about the saving potential for every old pump as well as the resulting CO2 reduction, and finally offered clear replacement recommendations. In all pump categories, convincing and economic alternatives to the existing "electricity gluttons" could be found.

After all, a total saving potential of almost 1.5 mio. kWh per year was determined if all existing, inefficient pumps in the complete garrison were replaced by state-of-the-art technology. Every year, more than 750 t CO2 emissions could be avoided. Replacing a bigger old pump of the "Wilo P 100/200" type by a modern electronically controlled "Wilo-Stratos 100/1-12" high-efficiency pump results in savings of around 10,200 kWh per year. This corresponds to the annual power consumption of two to three single-family houses.

By March 2010, around 15 % of the pumps had been replaced – not only broken pumps, but also – due to the high saving potentials – as a precautionary measure, i.e. the pump was still perfectly running. As early as in 2007, a 28 year old sub-distribution of the district heat supply was for example completely renovated. Since then modern Wilo pumps contribute to an energy-efficient heat supply of 51 buildings.

Today, the new pump technology already saves around 125,000 kWh electricity per year. By 2015, the pump replacement is to be completed. This comprehensive project of the US Army at the Baumholder site, which not only includes exhaustive installation of high-efficiency pumps, but also water-saving measures and the use of energy-saving fittings, was awarded the Environmental Award of the federal state Rhineland-Palatinate in June 2010.

American army media reported about this success worldwide and it found great resonance. In the meantime, other American bases asked for more detailed information and progress reports about the pumps installed.

Source: WILO SE