Ultrachem Pumps Help Backware Company to Clean Up

Certain process applications present difficult problems for pumps, particularly those involving aggressive chemicals. Mechanically sealed pumps can be prone to seal failure in some of these situations, leading to potential environmental contamination through loss of pumped media, resulting in expensive downtime. Ultrachem magnetically-driven pumps, available through liquid handling specialists, Michael Smith Engineers, are designed to meet the tough demands of these applications on the basis that 'extreme situations call for extreme measures'.

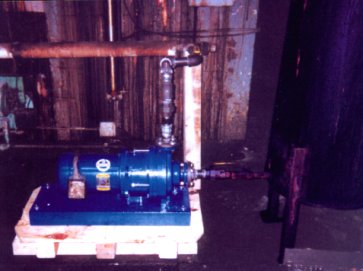

Ultrachem magnetically-driven pumps, available through liquid handling specialists, Michael Smith Engineers, are designed to meet tough demands.

One recent example where Ultrachem pumps have proved effective is with a company specialising in the washing of commercial bakeware. Here, large quantities of stainless steel bakeware contaminated with residual bread products require thorough cleaning. This meant a pump was needed to help perform a chemical mixing duty as part of the bakeware cleaning and deglazing process and involved mixing potassium hydroxide with diethylene glycol and hexylene glycol at 235 deg F (113 deg C)

The Ultrachem pump was selected to replace a mechanically sealed pump which was proving ineffective as the seals were lasting only 3-6 months. The liquid needed to be continuously re-circulated and mixed at high temperatures and contained not only the chemical cleaning agents but also the carbonaceous materials and silicates from the glazing agent.

Since installation some 18 month ago, the Ultrachem pump has proved a success on this challenging application, without any failures reported despite continuous service, seven days per week, 24 hours per day.

Ultrachem pumps are capable of delivering flows up to 75 m3/hr and heads to 100 metres. They incorporate a modified concentric volute to equalize pressure across the entire flow range which results in minimal hydraulic radial thrust loads, leading to reduced wear on the pump's components. This, combined with a rear sealing ring and holes in the impeller, balance the hydraulic axial thrust and serve to decrease pressure on the impeller.

A casing drain is standard on all these pumps simplifying maintenance by the back 'pull-out' design. Baseplates can be provided in steel or fibre glass. The option of a digital power monitor is also available to detect over and under load conditions. This protects the pump against dry-running and includes a current transducer and a 4-20 mA output for use with a PLC.

Source: Michael Smith Engineers