Tsurumi Pump Attached to Remotely Operated Vehicle in Radioactive Clean-up

A Tsurumi pump will be attached to a remotely operated vehicle (ROV) used in a novel radioactive waste clearing project at the specialised reprocessing plant of AREVA at La Hague site (northern France).

Tsurumi

The pump will help to transport radioactive sludge from special silos as part of an eight year recovery project.

Recycling has many forms. One of the most specialised is recycling spent fuel taken from nuclear reactors, which stands out for the highest safety concerns in material handling and process design. The La Hague reprocessing plant in the Manche region of France has the capacity to reprocess almost half the world’s light reactor spent fuel. The plant is embarking on a major new project to recover and condition radioactive sludge resulting from the chemical process of spent fuel recycling. This sludge is contained in several silos.

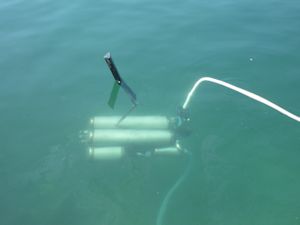

The project presents a number of technical challenges. Getting to the sludge itself is among the hardest as this can only be attempted through existing openings on the top of each vessel, and these measure just one metre across. To cope with the size restrictions and yet ensure that every corner of the silo is reached, a novel idea was conceived: a Tsurumi pump connected to a ROV will travel around the silo pumping sludge to a downstream treatment unit.

“We know there are several hundreds of applications for our pumps but this is something new,” says Daniel Weippert, managing director of Tsurumi Europe. “We design products to be the strongest and most durable machines on the market – and this is certainly one of our most difficult applications yet. This unique project shows the diversity of pumping projects in Europe and confirms Tsurumi as the supplier of the toughest pumps.”

Once lowered into the silo, the ROV will scour the entire silo and pump out the sludge to transfer it to the next stage of the treatment process. Because of the size of each silo – the largest measures 14 m long, 13 m wide and 10 m deep – the pump is expected to take two years to complete its part of the project.

Picking the right pump

Selecting the right equipment for the job was crucial. Size and weight limits were unavoidable but, more importantly, all machinery has to handle dense sludge. After extensive analysis, a KTV2-80 pump from Tsurumi was chosen because of its build quality and compact size. It will be cleaned regularly to ensure it continues working at its optimum performance levels.

The KTV2-80 is a powerful and yet compact pump built for ultimate wear resistance and durability. Weighing 38 kg, the pump is made from high quality parts and components including aluminium die casting and stainless steel. The pump’s 3 kW motor can transport liquid at a rate of up to 720 l/min with a head of up to 22.5 m.

Work to be done

The silo recovery project is currently in a lengthy prototyping and test phase. Among the key jobs are connecting the pump to the ROV, and constructing the sludge treatment and conditioning units to handle the radioactive waste. Thorough safety tests must also be conducted and all designs must meet strict safety authority approval. This means that recovery work is not due to begin until 2018.

The La Hague plant is owned and operated by the AREVA Group, a world leader in nuclear energy.

Source: Tsurumi (Europe) GmbH