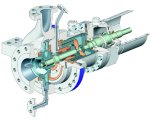

Sulzer Pumps – Leak-proof, Reliable, and Enduring

Process pumps which are used in refineries and chemical plants very often have to satisfy the highest demands for sealing. Sulzer Pumps has therefore extended its process pump series OHH with two hermetically sealed types, one with magnetic coupling (OHM) and the other with a canned motor (OHC). With these models, fluid transportation or delivery duties can be mastered in even the most difficult environment.

The process pump type OHH (see STR 1/2002, p. 4) is an overhung, horizontal, single-stage, radial-split, centerline-mounted, mechanically sealed heavy-duty process pump which has been designed and manufactured to fully comply with API standard 610, 9th edition. The mechanical seals and seal support systems fully comply with API 682, 2nd edition. The pump is characterized by its robust design, versatile application possibilities, and long reliable service life. A wide range of over 70 different sizes is available (see table). The OHH family has now been extended for sealless pump duties by the type OHM (with magnetic coupling) and type OHC (with canned motor).

Type OHM: with Magnetic Drive

Where mechanical seals no longer provide adequate security and zero emissions are a requirement, the type OHM magdrive pump may be applied (Fig. 1). The pump is designed and built in full compliance with the requirements of API standard 685 (sealless pumps). A magdrive coupling with strong permanent magnets ensures positive power transmission from the motor to the pump through the containment shell. Even though the system is inherently hermetically sealed, a backup secondary containment system with dry running gas seals provides extra security. This backup system is designed to withstand full operating pressure.

Where mechanical seals no longer provide adequate security and zero emissions are a requirement, the type OHM magdrive pump may be applied (Fig. 1). The pump is designed and built in full compliance with the requirements of API standard 685 (sealless pumps). A magdrive coupling with strong permanent magnets ensures positive power transmission from the motor to the pump through the containment shell. Even though the system is inherently hermetically sealed, a backup secondary containment system with dry running gas seals provides extra security. This backup system is designed to withstand full operating pressure.

Type OHC: with Canned Motor

For increasingly higher demands on sealing and security – i.e. when the secondary containment system is not allowed to have rotating seals – Sulzer offers the type OHC (Fig. 2), also compliant with API standard 685, 1st edition. The OHC is a canned-motor pump, manufactured in close cooperation with Hermetic-Pumpen GmbH , Germany, a long-standing partner of Sulzer Pumps (since 1994) and industry specialists in sealless centrifugal pumps.

For increasingly higher demands on sealing and security – i.e. when the secondary containment system is not allowed to have rotating seals – Sulzer offers the type OHC (Fig. 2), also compliant with API standard 685, 1st edition. The OHC is a canned-motor pump, manufactured in close cooperation with Hermetic-Pumpen GmbH , Germany, a long-standing partner of Sulzer Pumps (since 1994) and industry specialists in sealless centrifugal pumps.

The OHC pump overcomes also the most difficult and demanding pumping duties, for example:

OHM and OHC in Comparison

In some cases, the OHM pump may be higher in efficiency than the OHC. Since the motor is separate, it can be replaced without disturbing the pump. The pump can also be repaired without moving the motor. Repair work requires caution, but does not require specialists.

The OHC pump excels by having a motor casing that works as a safety containment without any moving seal. Moreover, it is very quiet and has no exterior roller bearings on the pump and motor. Its space requirement is smaller than the OHM since there is no need for a flexible coupling: Pump and motor are mounted on the same shaft.

Common for both types is that Net Positive Suction Head (NPSH) is uninfluenced by the waste heat from the drive. This is the case with the OHM thanks to a special circulation system (without cooling); and in the OHC thanks to an optional cooled circulation system with secondary impeller.

As all three types are based on a modular system, so the main hydraulic components are common and useable across the product family. Furthermore, it is possible to rebuild one configuration into another if required to accommodate application changes.

Operating Data

| OHH | OHM | OHC | |

| Ø suction branch in mm (inch) | 25-400 (1–16) | 25-200 (1–8) | 25-200 (1–8) |

| Max. capacity in m3/h (GPM) | 2250 (10,000) | 700 (3100) | 700 (3100) |

| Max. head in m (ft) | 330 (1100) | 330 (1100) | 330 (1100) |

| Max. pressure in bar (psi)) | 52 (750) | 52 (750) | 52 (750) |

| Temperature range in °C TD> | –40 to +425 | –40 to +260 | –120 to +425/TD> |

| Temperature range in °F TD> | –40 to +800 | –40 to +500 | –185 to +800 |