Siemens PLM Software Facilitates Energy-Saving Heat Pump Development

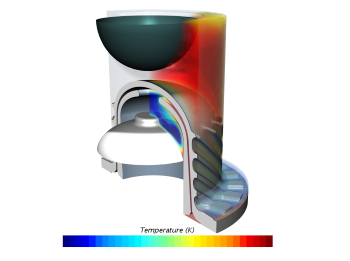

A very high number of components can be included in the simulation and multi-disciplinary simulations can be achieved in a single user interface by using Simcenter Star-CCM+. (Image source: Siemens AG)

A very high number of components can be included in the simulation and multi-disciplinary simulations can be achieved in a single user interface by using Simcenter Star-CCM+. The optimum design of the ThermoLift solution allows the energy costs for the heating, cooling and hot water systems in a building to be reduced by 30 to 50 percent compared to conventional systems.

Most people in the USA use ovens or boilers to keep their houses and apartments warm. Only a small number use heat pumps which heat the buildings using environmental heat. These units are often electrically driven and this is the starting point for the founders of ThermoLift, Dr. Peter Hofbauer und Paul Schwartz. Their ThermoLift system for a modern heating, ventilation, and air conditioning (HVAC) system is similar to a standard Vuilleumier heat pump but uses a special temperature cycle (the TC cycle). In order to improve the simulation-led design process, ThermoLift has been working for a few years with the Simcenter simulation software from the Siemens PLM Software portfolio.

Precise simulation of extremely complex physics

A conventional Vuilleumier heat pump moves a gas such as helium between three chambers in a closed system. Two so-called displacers slide back and forth inside a cylinder. The expansion or compression of the gas occurs due to the cold or hot thermodynamic cycle. The particular feature of the ThermoLift device compared to a Vuilleumier heat pump is that the displacers are controlled separately from the mechatronics in order to provide better control of the displacer movement, and therefore the thermodynamic cycle. The whole ThermoLift system consists of several modules such as the heat exchanger, regenerators and displacers which are produced during the design process. ThermoLift chose Simcenter Star-CCM+ for the simulation and modelling of the complex physics involved. The software is a comprehensive solution which allows multi-disciplinary simulation in a single user interface. In addition to this, Star-CCM+ allows more components to be integrated into the simulation which speeds up the design process and produces even more accurate results.

Economical and reliable

The ThermoLift system’s optimized design process means that the energy losses can be reduced significantly compared to conventional Vuilleumier heat pumps. This leads to energy cost savings of 30 to 50 percent. The displacers’ ‘soft landing’ also reduces machine noise while achieving operating times of over ten hours.

Source: Siemens Aktiengesellschaft