Siemens Expands Its Simotics XP Portfolio With New Motors

The Siemens Drive Technologies Division has supplemented its Simotics XP portfolio with explosion-proof 1MB10 motors which are available in efficiency classes IE1, IE2 and IE3.

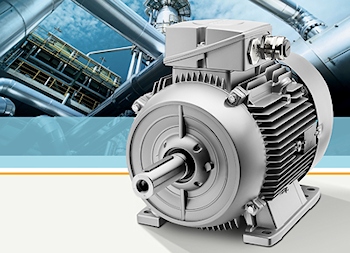

The Siemens Drive Technologies Division has supplemented its Simotics XP series with explosion-proof 1MB10 motors which are available in efficiency classes IE1, IE2 and IE3. (Image: Siemens)

The 1MB10 motors have been designed to enable pumps, fans and compressors and meet all requirements that provide maximum safety within an Ex environment.

These explosion-proof 1MB10 motors belong to the Simotics low-voltage motors from Siemens. They are available in dust explosion protection (Ex t) and in non sparking design (Ex nA). The motors find their conventional usage in Zones 21/22 (dust) and Zone 2 (gas-vapor-mist) which has been classified in accordance with the directive 94/9/EC (ATEX 95) regarding equipment and protective systems intended for use in potentially explosive atmospheres.

The 1MB10 motors are the modified version of standard 1LE10 series. All the motors are available in efficiency class IE1 (Standard efficiency), IE2 (High efficiency) and IE3 (Premium Efficiency) and henceforth contribute in the adequate reduction of energy costs and CO2 emissions during their operation.

The motors cover a performance range from 0.75 kW to 18.5 kW and are available in shaft height ranging from 100 to 160. The 1MB10 motors are identical in design with the 1LE10 standard motors.

In the chemical and petrochemical industry explosion hazards are ubiquitous. Such hazards are also present in the wood industry or for example in the agricultural sector as well. Ignition risks are highly probable due to gases, fumes, mist or dust present in high concentration that get easily mixed with oxygen in the air and release the so-called minimum ignition energy - required to ignite a combustible particle. Legislators in many countries have implemented appropriate stipulations in the form of regulations based on national and international standards to ensure maximum safety in these areas.

Source: Siemens Aktiengesellschaft