Siemens Completes Range of Low-voltage Motors for Flexible Deployment

Siemens has completed its spectrum of Simotics FD low-voltage motors. The new motors, covering the output range from 200 to 1,600 kilowatts and with shaft heights ranging between 315 and 450 millimeters, are optimized for converter operation and are particularly energy efficient, especially in the partial load range.

Because the modular concept enables users to choose for example between air cooling and water cooling or between self-ventilation and forced ventilation, the Simotics FD motors can be adapted to suit extremely diverse applications. (Image: Siemens AG)

In combination with Sinamics low-voltage converters, they form an Integrated Drive System (IDS) that meets the requirements of the IES2 system efficiency class. Compared to the reference system of the standard, this means that losses are reduced by 35 percent. The modular structure provides customers with maximum flexibility, allowing them to choose for example between air cooling and water cooling or between self-ventilation and forced ventilation. Service concepts such as predictive condition monitoring round off the portfolio.

The Simotics FD motors are ideally suited for use with Sinamics low-voltage converters and, as part of an IDS, offer a cost-effective, energy-efficient complete system that generates very little noise.

In combination with the Sinamics low-voltage converters, the drive train meets the requirements of the IES2 system efficiency class. If the entire drive system is water-cooled, heat recovery can be used to boost efficiency even further. Because the power density of the water-cooled motors is up to 30% higher, they are extremely compact.

The terminal box can be rotated in steps of 90 degrees, is diagonally divided and has a large format, making it particularly easy to connect. Comprehensive service, ranging from online condition monitoring and repair right through to retrofitting, is ensured via the global service network. The innovative and compact new motor design is compatible with the Simotics TN series N-compact. It has no need for external cooling ribs; these are integrated directly in the stator core in the rectangular gray cast-iron enclosure, enabling cooling to take place in the enclosure close to the heat source.

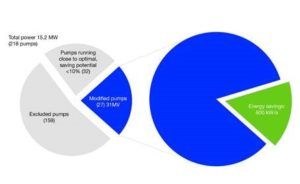

The Sinamics G120P converter and Simotics FD motor combination has been designed specifically for pump-and-fan applications, where it performs particularly well. Simotics FD motors are now used widely across all sectors, including plastics, cement, mining, steel, marine, paper, crane, water/wastewater and chemical. Thanks to the latest addition, they now cover the entire output range.

Source: Siemens Aktiengesellschaft