Saer Reasons by “Finite Elements”

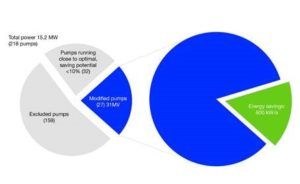

Energy saving, what does it mean? The concept could be seen as a limitation, since usually speaking it is meant to be a decrease in the use of energy. But the real aim is to reduce the waste by keeping the same levels of performances through the increase of efficiency and functionality.

Testing Room (Image: Saer)

The italian Company Saer Elettropompe S.p.A. has been committed to this philosophy since long time. In its D&R department, all the products have been studied in order to reach efficiency improvements to reduce the amount of required energy.

The laboratories are equipped with CFD calculation software, working on the finite elements. It is a state of the art technology which allows Saer engineers to study the best hydraulic efficiency which can be translated in energy saving, especially when the pump is running 24h/day.

This software helps to project the blade and diffuser’s outline for both surface and submersible pumps and the volute casing of surface pumps too. The geometries are transformed in mathematical models: in this way even before the testing room phase, flow head and absorbed power datas are available. The mathematical model can be modified in order to improve the performances in percentage points and to decrease the absorbed power. Moreover SAER has the possibility to test the projected parts even before the casting, through the prototype machine. All the trials on the pumps and motors are made in the two internal modern testing room, able to test over 4000m3/h, and over 500 Kw.

All Saer multistage pumps have been developed in order to create the best performance machines. It is the same as for the new bareshaft NCBK series, which will replace the old NCBT one: the Italian Company has improved the total efficiency, an aspect which is even more important in cases of a big power ranges. Even on the submersible pumps series Saer has already made enhancements on the hydraulic profiles: the activity has been directed to the blades shape, which has been developed in order to have top fluid-dynamic results and to the shaft shape, in order to find the best solution to avoid vibrations. In addition within April 2011 the review of all electric motors will be finished: this will mean more efficiency accoding to the European Law that is coming into force starting from June 2011. Even for the electric motors Saer is using software working on finite elements for performances/risk project and study, controlling all the variables that may influence the best return. Moreover, the application of the VFD (inverters) on our pumps allows motor speed regulation according to the implant request: this means better responses to the flow/head peaks and reduction of energy wasting in scarce performance period. Concerning the new Split Casing pumps, the structure itself of the SKD model requires low maintenance cost and low life cycle cost thanks to low vibration design, minimum shaft flexion, minimum axial trust on the shaft and minimum components wear, which is reached through to the material selection.

Saer produces entirely in Italy, using only the top quality material: cast iron EN-GJL-250, carbon steel G20Mn5, bronze marine G-CuSn10, Stainless steel AISI 316 (1.4408), different gradations of DUPLEX and SUPER DUPLEX. All these materials have not only a high mechanical resistance but also high corrosion resistance.

The extended range of Saer is the right solution in the clean water field: since 1951 Saer Elettropompe manufactures water electric pumps and motors for the civil, industrial, agricultural and domestic field; the products are suitable for municipalities, firefighting applications and for conditioning and heating, naval and mining sector. The range includes:

- Normalized pumps according to EN733 and pumps exceeding the norm, availables in different typology (close coupled, with stub shaft or bareshaft), and many materials (carbon steel, cast iron, bronze, stainless steel) from 0,75 to 500 kWs of power.

- Submersible pumps (from 4" to 14") and motors (from 4" to 12") up to 300 kWs of power and in different metallurgies (carbon steel, cast iron, bronze, stainless steel, DUPLEX ).

- Vertical and horizontal multistage pumps , with powers from 0,75 to 500 kWs.

- Split casing pumps availables from 15 to 1500 kWs.

- Pumps for domestic applications and booster sets.

Saer Elettropompe Company is certified ISO 9001:2008.

Source: SAER Elettropompe S.p.A.