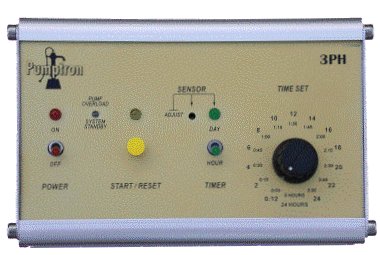

Protection and Control for Submersible Pumps

Why should you use Pumptron instead of a conventional Borewell controller? The answer is quite simple: Pumptron, eliminates the need for probes to detect water levels or flow valves and pressure valves to detect water flow - devices that are expensive and proven to be unreliable.

Consequently Pumptron significantly reduces the cost and simplifies the overall installation providing high reliability.

The reason being conventional Borewell Pump Controllers have sensors that control the pump, over time these sensors develop a build up of mineral deposits and other materials. If the Borewell is dry, and water drops on the sensors from higher in the Bore, the controller can turn the pump on.

As the Bore replenishes itself the pump can still be turning, this makes the pump cavitate, until such time that there is enough water in the Bore to "break through the cavitation effect"

The result being the motor is pumping “dry”, which can destroy the pump and damage the turbine. This is especially the case if this is repeated which is frequently the case. What has been needed is an intelligent controller that knows if the pump is pumping “Air”.

The cost of withdrawing the pump, having it replaced and having it replaced in the bore can cost 6,000 Euros. Pumptron will solve this problem for a fraction of this cost.

For Further Information please visit

Source: Pumptron