Pressure Exchanger Cuts Desalination Costs on Malta

In early July 2008, an isobaric energy recovery system developed by KSB started operation in the Pembroke seawater desalination plant on Malta.

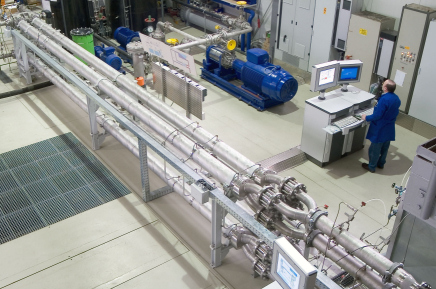

The “SalTec” pressure exchanger helps to cut costs in the Maltese RO desalination plant.

Consisting of two SalTec DT250 operating in parallel, the system uses hydraulic power transmission to reduce energy costs compared with conventional solutions, such as turbines, for example.

The key element is a pressure exchanger which transfers the energy of the concentrated brine directly to the raw seawater without the need for mechanical conversion. An electronic control system records all operating modes of the higher-level reverse osmosis (RO) system and adjusts pump and pressure exchanger control as required. It ensures that the water column in the pressure exchanger vessels is accelerated and decelerated so gently that switching the rotating valve of the pressure exchanger does not cause pulsations.

KSB also supplied the high-pressure pump employed to generate the pressure required for the reverse osmosis process and the booster pump used to compensate for the pressure losses in the pressure exchanger circuit. All components are designed to ensure that the production costs for a cubic metre of desalinated water are lower than those of other systems. KSB is the first manufacturer to supply this type of all-in package for the RO process.

The Pembroke plant produces more than 40,000 cubic metres of desalinated water per day and is therefore an important drinking water supplier, both for 400,000 inhabitants and for more than one million tourists who visit Malta every year. By using state-of-the-art pumps and pressure exchanger technology, the plant operator uses around 35 % less energy.

Since as early as August 2003, a SalTec pilot system has been operating in Frankenthal and a further system in Sharm El Sheik, Egypt, since mid-May 2004.

Source: KSB SE & Co. KGaA