News from the IFAT 2005 – Part 3

In this third part of the IFAT report impeller.net moves down the alphabet and talks about innovations from companies starting with Iwaki.

Iwaki extends the MDM series it has already introduced at the ACHEMA by two models for heads up to 72m. The process centrifugal pumps made of fluororesin were designed according to a robust and simple construction and easy maintenance. To guarantee the max. pressure of 16 bar the rear part of the casing was carbon fibre reinforced ETFE (CFRETFE). The new MDM models are suitable for applications of small flows with high heads.

Another new product is the magnetic drive turbine pump of the MDT series used in medical cooling systems as well as the so called Flowcheckers. The latter are made for applications to control broken or closed pipes and also send an alarm at the entry of gas or air. That makes them especially suitable for the pumping of degasifying media often used in disinfecting applications.

At the IFAT 2005 waste water specialist Jung Pumpen presents for the first time their new control program. The microprocessor controls (EasyLogo) of the manufacturer will in the future also ensure automatic intelligent regulation in follow-up time. Manual adjustment becomes obsolete both upon installation and during operation. Parameterising, televising and teleoperation will in the future be possible through new HighLogo controls. To this effect the proprietary software "HighControl" provides valuable services. The new pressure pipe flushing systems by Jung Pumpen are convincing in particular through their operational safety with at the same time optimal efficiency: The systems are based on compressors tried and tested over many years and are completely pre-assembled - the costs for assembly on site are correspondingly low. The motors operating entirely without grease are low in maintenance and make an important contribution to environmental protection. The low noise systems by the drainage specialist in Steinhagen are complimented by a broad program of accessories included in the scope of delivery: From the operating hour meter over a master switch to the integrated heater for hard days of frost the new pressure pipe flushing systems possess all attributes for an economical efficient and reliable municipal drainage.

The new pressure pipe flushing systems by Jung Pumpen are convincing in particular through their operational safety with at the same time optimal efficiency: The systems are based on compressors tried and tested over many years and are completely pre-assembled - the costs for assembly on site are correspondingly low. The motors operating entirely without grease are low in maintenance and make an important contribution to environmental protection. The low noise systems by the drainage specialist in Steinhagen are complimented by a broad program of accessories included in the scope of delivery: From the operating hour meter over a master switch to the integrated heater for hard days of frost the new pressure pipe flushing systems possess all attributes for an economical efficient and reliable municipal drainage.

With the new "PKSD 1000" Jung Pumpen is offering a tailor-made plastic duct which presents in combination with the channel impellers MultiStream and the vortex impellers MultiFree as well as a deposit-free collecting chamber especially manufactured for this duct a reliable and cost efficient solution.

With the new "PKSD 1000" Jung Pumpen is offering a tailor-made plastic duct which presents in combination with the channel impellers MultiStream and the vortex impellers MultiFree as well as a deposit-free collecting chamber especially manufactured for this duct a reliable and cost efficient solution.

The so called SBR units with submersible motorised aerator have strongly gained in importance over the past years. SBR means "Sequential Batch Reactor" which translates into periodically adding oxygen to the waste water and stirring. The new SBR system by Jung Pumpen combines the reliability of the known submersible motors and disposal units of the production site at Steinhagen with the benefits of this progressive clarification technology. The SBR system can be fitted into existing units in the context of restructuring measures and provides reliable services as central system component for fully biological small scale clarification plants for 4 to 12 inhabitants.

Köster has specialized in manufacturing propeller pumps which feature extremely high endurance. The latest development in this area introduced at the IFAT were new bearing materials.

Increased reliability and improved efficiencies are the features of the Amarex KRT series by the German pumps and valves manufacturer KSB. The new models of this type series designed for handling municipal and industrial waste water feature a closed jacket cooling system around the motor. Thanks to the closed cooling jacket, the motor heat is dissipated by the fluid handled, whether the motor is submerged in the fluid or not, resulting in optimum heat dissipation under all operating conditions. A separate water/glycol circuit transports the heat from the cooling jacket to the fluid-cooled section of the pump casing. As there is no hydraulic connection with the fluid handled, the cooling circuit cannot be contaminated. The new models are suitable for both dry- and wet-well installation.

Increased reliability and improved efficiencies are the features of the Amarex KRT series by the German pumps and valves manufacturer KSB. The new models of this type series designed for handling municipal and industrial waste water feature a closed jacket cooling system around the motor. Thanks to the closed cooling jacket, the motor heat is dissipated by the fluid handled, whether the motor is submerged in the fluid or not, resulting in optimum heat dissipation under all operating conditions. A separate water/glycol circuit transports the heat from the cooling jacket to the fluid-cooled section of the pump casing. As there is no hydraulic connection with the fluid handled, the cooling circuit cannot be contaminated. The new models are suitable for both dry- and wet-well installation.

Another important exhibit of pumps and valves manufacturer KSB will be the new "PumpDrive" speed control system. As a pioneer in large, variable speed pump drive design, the company will present its latest generation of speed control systems for ratings from 0.55 to 45 kW. The new "PumpDrive" can be directly mounted to the motor, to the wall or in a control cabinet and is available in assorted variants kitted out with optional functions. Several units are able to communicate with each other, allowing the user to operate several pumps at the same time by means of the integrated control feature. KSB is the only manufacturer currently offering a motor-mounted speed control system for pumps up to a rating of 45 kW.

Another important exhibit of pumps and valves manufacturer KSB will be the new "PumpDrive" speed control system. As a pioneer in large, variable speed pump drive design, the company will present its latest generation of speed control systems for ratings from 0.55 to 45 kW. The new "PumpDrive" can be directly mounted to the motor, to the wall or in a control cabinet and is available in assorted variants kitted out with optional functions. Several units are able to communicate with each other, allowing the user to operate several pumps at the same time by means of the integrated control feature. KSB is the only manufacturer currently offering a motor-mounted speed control system for pumps up to a rating of 45 kW.

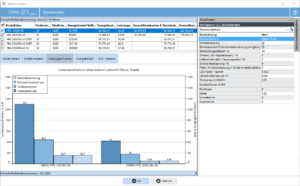

As one of the first pump manufacturers to do so, KSB is introducing software specially designed for selecting dry well and wet well waste water pumps. The new "Helps" program, which can be implemented worldwide, supports consultants and plant operators in designing waste water transport and treatment systems. It is a reliable and intuitive tool for selecting and configuring the requisite pump units. Thanks to a comfortable interface, users can find a suitable pump in just three steps. The program enables users to copy selected data and drawings to the plant planning system. A precise CAD drawing, which includes the selected installation options, is available for each pump. In addition, the user receives detailed tender texts for the respective pump. There is no need to install "Helps" on the computer in order to use it.

Helps was developed by VSX – VOGEL SOFTWARE, the specialist for software and Internet solutions for the pump industry.

Helps was developed by VSX – VOGEL SOFTWARE, the specialist for software and Internet solutions for the pump industry.

A chopper-pump takes care of chopping solid parts, mixing and emptying in the Landia BioChop hygienisation unit. The system – in accordance with EC regulations – for use of by-products from the food industry comes with a control unit to control and register the hygenisation process. The BioChop hygienisation unit is characterised by its simple design with operationally reliable high-quality components. Application areas are diverse, one of them is e.g. the fish and poultry processing companies.

A chopper-pump takes care of chopping solid parts, mixing and emptying in the Landia BioChop hygienisation unit. The system – in accordance with EC regulations – for use of by-products from the food industry comes with a control unit to control and register the hygenisation process. The BioChop hygienisation unit is characterised by its simple design with operationally reliable high-quality components. Application areas are diverse, one of them is e.g. the fish and poultry processing companies.

Lowara presents its new SV pump series for demanding technical solutions and extended application areas. These vertical multi stage centrifugal pumps in stainless steel were optimized in design and the several sizes were added to the range. The multipurpose pumps can be used for water supply and treatment, industrial and agricultural applications as well as H.V.A.C. All used materials are approved for usage with drinking water.

High performance, substantial energy saving and reduced operating costs are the impressive characteristics of the new ZN8 submersible pumps – also by Lowara. Thanks to the great design and highest quality workmanship the manufacturer guarantees a max. efficiency of 80-82%. The exclusive “dynamic” wear ring reduces hydraulic losses. The use of precision castings to obtain very smooth surfaces and reduce tolerances to a minimum, thereby contributing to enhanced pump performance. With an 8" diameter, flow-rates up to 180 m3/h and heads up to 550 m means that the pumps can be used in aqueducts for supplying drinking water, in water pressurization and distribution installations for civil and industrial use, and in irrigation systems for farms and large green areas such as parks and golf courses.

The new MAGDOS LC developed by Lutz-Jesco is an inexpensive solenoid-driven diaphragm dosing pump. The pump is ideally suited for simple and continuous chemical feed applications in the water and wastewater treatment sector as well as the process industry. The newly designed drive-solenoid is sealed in a water-proof, NEMA 4X housing. The MAGDOS LC operates at 120 strokes per minute and is controlled via ON and OFF of the main power. Tubing connections are integrated into the check valve housings. The MAGDOS LC dosing pump is available in three sizes with capacities up to 5.7 liters per hour against a pressure of up to 10 bar. The manual stroke length control enables the user to adjust the pump’s capacity continuously between 20 and 100% of its maximum capacity.

Source: Messe München GmbH