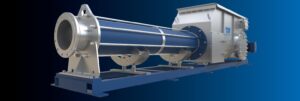

New VOGEL Multistage products … something to really get pumped about!

Ring section multistage pump designs have long been known to provide efficient, cost effective solutions for high pressure pumping applications. Their modular design maximizes interchangeability while allowing the units to be very closely matched to the customer's hydraulic condition.

Variants in mounting configurations and flange orientation make this type of product one of the most versatile available today. Goulds new model MP is all of the above and more!

Performance Range:

Capacity 1500 usgpm (340 m3/h)

Head 1640 feet (500 m)

Temperature 280°F (140 °C)

Casing Pressure 800 psig (55 bar)

Applications

Water supply booster systems, fire fighting, cooling circuits, boiler feed, condensate, heating, reverse osmosis, ultra filtration, cleaning systems, shower pumps for pulp & paper and in various places in the mining industry.

Design Flexibility:

The model MP has a host of design features which provide customers with the highest level of performance combined with low life cycle costs.

Mounting

The MP is available in horizontal, vertical or even vertical lineshaft design to meet a wide variety of installation requirements. All versions have suction and discharge flanges that can be rotated in 90° increments. Flanges are available in both ANSI or ISO drilling and the units can be furnished in a close-coupled configuration.

Hydraulic Coverage

Low flow, high head applications are a strength of the MP's. It needs only four sizes to cover the entire range from 0-1500 usgpm and up to 1640 ft of head. Using the extension of the MP - the P range - it's also possible to attain flows up to 9000gpm! The modular design truly allows for maximum flexibility within a particular size or group. Operation at either 50Hz or 60Hz is no problem.

Balancing

Conventional designs use balancing devices to even out loading. These normally require very tight clearances in wear areas to maintain circulation in the balance line. Thrust balance in the MP is achieved via balance holes in the impellers.

Stuffing Box

The MP can accept packing as well as single or double mechanical seals. The standard stuffing box is a self-venting Taper Bore design which helps extend seal life. Internal flushing of the stuffing box is also standard and eliminates the need for any auxiliary flush piping for most seals. A big advantage to any user!

Inducer Technology

The model MPAI (end suction) is also available with an inducer. This technology allows the unit not only to handle applications where NPSH is low, but due to the advancer research which has been done it also makes it an ideal options for handling liquids close to vaporization or liquids with entrained air.

Materials of Construction

Unlike other competitive products on the market today, the MP is available in a wide range of materials including CI, CS, DI, 316SS construction. This wide range of materials makes the MP a truly versatile product capable of servicing in traditional boiler feed services and also in many chemical applications. This versatility will enable customers to reduce the number of pump types on site and also to hold less inventory. Other materials are also available on request.

Modular Design = Reduced Inventory

The inherent advantages of a ring section pump are that they require minimal inventory to support a wide range of hydraulic conditions. The MP has been designed such that there are only four sizes and therefore a limited amount of parts needed to support or modify the units once installed.

Something to talk about!

Evidence of a great design is seen in the success we have with the product. Recently Goulds was awarded an large order for multistage pumps at a mine in Southern Peru. This project was a classic example of the customer realizing in the end the advantages a ring section design has over the traditional horizontal split multistage. Despite all the competitions effort, Goulds secured the order for this project in excess of $1M usd. Proof that superior product, determination and our drive to be the best wins every time.

Source: Xylem Inc.