New unique Pump Installation Concept

ABS is introducing a new, unique concept combining the possibility of faster installation, and thus shorter project lead times, with improved reliability and operating conditions. System PMI™ (Pump Mill Integration) provides true flexibility both now and in the future.

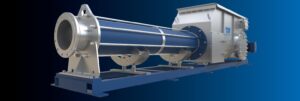

Is it possible to achieve quicker pump installation, shortening project lead times, and get improved reliability and operation conditions at the same time? The latest innovation from ABS is as simple as it is revolutionary: put the pump and motor on one single, heavy concrete baseplate, but do not attach it to the floor. The new System PMI™, Pump Mill Integration, means:

Ease of Project Engineering

Time-consuming planning and grouting-in of baseplates is no longer required. Just provide enough space for the free-standing unit, and considerable time and costs in project planning and mill construction can be saved.

Improved Operating Conditions

Pipe strain on machinery equipment, as well as coupling misalignment, normally cause costly maintenance and downtime. The new ABS solution, where the pump and motor are mounted onto a rigid baseplate forming one single unit which is not attached to the floor, minimises the effects of stresses on alignment - a critical point in every pump installation. A free-standing installation also minimises the effects of vibrations and shell sounds.

Altogether, the improved operating conditions result in longer lifetime for the pump, seal and coupling and thus a lower Life Cycle Cost.

Future Flexibility

The new System PMI™ not only gives flexibility at the initial installation, but also for the future. Moving and relocating pumps during a plant rebuild is easier than it has ever been, and upgrading the pump and/or motor for increased output can be achieved without any civil works.

System PMI™ is already operating successfully, saving time and money all around the world.

Source: Sulzer Ltd.