New Standardised Chemical Pump for the Global Market

At this year’s ACHEMA (18 to 22 June 2012) in Frankfurt, the KSB Group, Frankenthal, Germany, will debut the latest generation of its standardised chemical pumps.

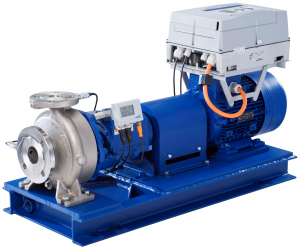

The new MegaCPK type series from KSB’s Pegnitz factory equipped with the PumpDrive variable speed system and the PumpMeter monitoring unit. (KSB Aktiengesellschaft, Frankenthal)

The new MegaCPK type series distinguishes itself above all by a high output per size and hence very low energy consumption. It is an advanced version of the internationally successful CPK, CPKN and Megachem type series. At identical operating data and conditions the user can select smaller pump sizes compared with previous generations and competitor products. This will not only save energy during operation but will also reduce initial investment costs.

In order to minimise the risk of cavitation, KSB’s development engineers put special emphasis on good suction behaviour at a low NPSH value. This is why even under tough operating conditions the pumps will run quietly and smoothly. Their reliability is thus ensured and the availability of the entire system is increased. With the help of the finite element analysis (FEA), a calculation method for structural simulation, it was possible to increase the pump sets’ rigidity. Another benefit in this respect is the optimised single-piece bearing bracket. The easy-to-service mechanical seals, fully confined casing gaskets and minimal axial thrust ensure long pump service lives and reduced life cycle costs since the owners/operators spend less on maintenance and repair. As is common practice with all industrial pumps by KSB, the pumps delivered to the owner/operator are provided with impellers whose diameters are matched precisely to the operating point. In addition to the large variety of pump sizes on offer, this is the only way to ensure that the pumps require as little energy as possible. For special applications, a range of models and material variants are available, allowing to also transfer fluids that require heating or cooling. Manufactured at production sites in Europe, Asia and South America, the new type series is integrated in a production and service network which means a high level of availability for owners/operators.

Source: KSB SE & Co. KGaA