New Materials for Highly Flexible Flange Coupling

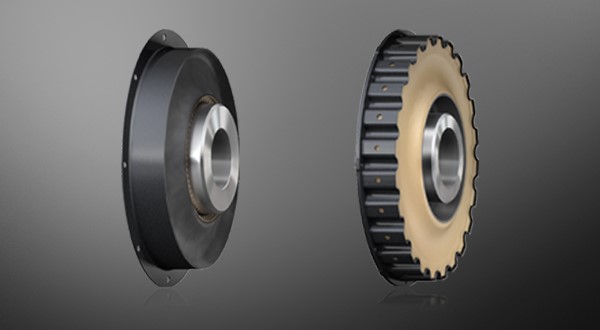

Illustration on the left: SINULASTIC B with material synthetic rubber (EPDM); illustration on the right: SINULASTIC A with material silicone rubber (SI). (Image source: KTR Systems GmbH)

Main applications are diesel engine drives for power generators (so-called gen sets), heavy construction machines, compressors, gearboxes and large hydraulic pumps.

With SINULASTIC designed as a flange coupling having a radial load path, the highly flexible elastomer elements are used between the flange ring and the coupling hub. Here they dampen torsional vibrations brought into the system by the engine shifting the operating range above the critical resonance speed. Depending on the Shore hardness of the elastomers, twisting angles from 13° to 18° are achieved.

The product line has been available from KTR in natural rubber (NR) in different rubber qualities with a linear torsion spring characteristic curve up to now. We extended the SINULASTIC by two dynamic properties by means of the new elastomer materials: With the synthetic rubber (EPDM) the torsion spring stiffness has a low decline, while it behaves lightly progressively with the silicone rubber (SI). The new materials are specifically adapted to the increased demands on high temperatures of the last developments in the range of I. C.-engines, for example the new exhaust gas levels and the accompanying higher operating temperatures.

„We are perfectly positioned for adjusting the optimal torsional vibration situation of every application by the broad product line relating to temperature resistance and torsion spring stiffness“, Marie-Christin Maier, product manager of KTR, explains. „We will be able to realize ambient temperatures up to + 130° C for bell installation or free standing installations in the future.“

The modular design of SINULASTIC allows to use the new elastomers either as a single row or dual solution with two elements connected in parallel.

The product line comprises four designs in total which are fully compatible with regard to connection geometry, mounting space and technical data in spite of their individual characteristics so that there always is an optimal solution for the individual drive task. The designs are available in eight sizes each for rated torques from 1,750 to 25,000 Nm and the three different materials natural rubber (NR), synthetic rubber (EPDM) and silicone rubber (SI).

Main applications of SINULASTIC are diesel engine drives for power generators (so-called gen sets), heavy construction machines, compressors, gearboxes and large hydraulic pumps.

The new materials in brief

Synthetic Rubber (EPDM)

- Max. ambient temperature: +100° C

- Long service life

- Low decline of torsion spring stiffness

- High weather and ageing resistance

- High damping

Silicone Rubber (SI)

- Max. ambient temperature: +130° C

- Very good media resistance with oils and greases

- Lightly progressive torsion spring stiffness

- High weather and ageing resistance

- Very high damping

Source: KTR Systems GmbH