New Improved Filter Press Solution from Tapflo

Tapflo is proud to announce that a series of changes have been implemented in the TF pump range in order to assure better pump operation and handling.

Main changes include new standard of reinforcement plates, booster holders and booster supplier. Tapflo has introduced Festo booster as its standard solution.

“This product improvement confirms that nothing is perfect. Despite being market leader in Filter Press applications Tapflo managed to develop quality and reduce the list price at the same time. Currently Festo has become Tapflo’s standard supplier what ensures a high quality, perfectly matched booster but in the same time lower price!” says Adam Pszczoła - Tapflo Products Area Manager.

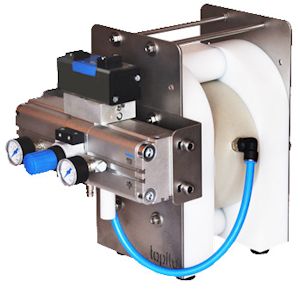

The Tapflo pump for filter press feeding is a very compact unit that can be mounted directly to the filter press. According to Mr. Pszczoła the design and function allows the user a straightforward pressing of slurries.

A pressure regulator is already mounted on the unit. The pumps are based on standard metal and plastic Tapflo pumps. Furthermore an external pressure booster doubles the delivery pressure. For example, with available air pressure of 7 bar, the delivery pressure will be maximum 14 bar.

Features & Benefits

- Optimal pressure amplification: The output pressure can be regulated up to 2:1 of input pressure

- Plug & Play: The pressure booster is mounted directly on the pump making it a small and compact unit that can be assembled on the filter press

- Simple operation principle: Due to its working principle the TF pump does not require any automation nor complicated safety features for proper operation

- Robust design: Best durability thanks to balanced diaphragms and high pressure pump concept

- Special design: Using of reinforcement plates, pin screws and a hybrid air valve ensures reliable and maintenance free operation under high pressure

- Diversity: All Tapflo pumps can be supplied with a booster making the range appropriate for almost any application.

Delivery scope

As a standard the pump is supplied with the following items:

- Complete pressure booster: a. Quick air connection for air supply; b. Muffler; c. Pressure regulator; d. Two manometers – input and output pressure

- Reinforcement plates (plastic pumps) / Special pin screws (metal pumps)

- Mounting plate with screws

- Air connection between the pump and the booster

Complementary products

- DTF dampener: The offer consists also of Tapflo active pulsation dampener prepared to work under higher pressure. The pulsation dampener is the most effective way to remove pressure variations on the discharge of the pump ensuring a stable and continous flow into the pipeline. In the same way as with the pump, the plastic dampener is reinforced on both sides by metal plates to ensure bester rigidness of the whole assembly.

- Air treatment system: To ensure best air quality and therefore longest life of products, Tapflo offers a complete air treatment system. It can consist of the following devices:

- Filter regulator

- Needle valve

- Water separator

Picture: Tapflo

Source: Tapflo AB