Netzsch: Pump Technology for Maritime Applications

Netzsch Pumpen & Systeme has developed four different product lines, which can be universally applied as transfer and booster pumps on ships and shipyards, as well as on offshore platforms – from fuel or sludge transport, through loading and unloading, to stripping.

To serve the full range of requirements for maritime use, Netzsch has developed four different product series, which can be universally deployed as transfer and booster aggregates on ships and wharves, as well as on offshore platforms. (Image: Netzsch)

Nemo progressing cavity pumps, which cope particularly well with highly viscous media thanks to their special conveying principle, are therefore suitable for oil sludge or wastewater. The more compact Tornado rotary lobe pumps, which enable a higher flow rate, are used to transfer wastewater, as well as to load and unload various media. On the other hand, Notos screw pumps, are ideal for transporting lubricant oil, fuel and chemicals. The pumps can also be supplemented by high-performance Netzsch macerators for the grinding and separation of larger, harder objects, primarily when conveying wastewater.

Thanks to their conveying principle, Nemo progressing cavity pumps can also cope with liquid media that contain solids, which means they are for instance frequently used on passenger and container ships to convey wastewater.

Pump for highly viscous and polluted media

With this displacement technology, the consistency, and especially the viscosity, of the medium are insignificant in terms of the product flow. This is why the Nemo pumps, are not only used for wastewater, but also for pumping media, including oil residues and sludge, on oil tankers and cargo ships and even mixtures of oil, gas and sand on offshore platforms. The progressing cavity pumps are also suitable for stripping and cleaning oil tanks on wharves.

In addition a Netzsch macerator, either the M-Ovas shear plate macerator or the N.Mac double-shaft grinder, which grind or separate hard and heavy particles, can also be used for wastewater. It is installed in the wastewater circuit upstream from the pumps and thus avoids clogging or blocking due to solid contents.

Compact model for limited space on board

Because space is limited, especially often on ships, there is another type of pump, the Tornado rotary lobe pump, which is ideal for the maritime sector, as it has a particularly compact design, while at the same time ensuring a high flow rate. The displacement element in these pumps are two rotary lobes that rotate in opposite directions, thus transporting the media smoothly but continuously. Again, the delivery rate is independent of the viscosity of the medium. The design of the Tornado T2 type pumps is particularly well suited for the demands of use on the high seas: they not only fit into the limited space available on board, but also reduce expenditure on spare part stock and maintenance. Instead of a complex and bulky timing gear, the aggregate has an oil-free synchronised gear with belt drive which reduces the weight of the pump by at least 30 percent and ensures a very small installation depth. In addition, the whole mechanism is less susceptible to faults, which means the range of spare parts can be kept very low.

The uses of these pumps, which have a conveying volume of up to 1,000 m³/h in spite of their small size, include loading and unloading, but also transferring used industrial oil, multiphase mixtures and drill cuttings and drilling sludge on oil platforms.

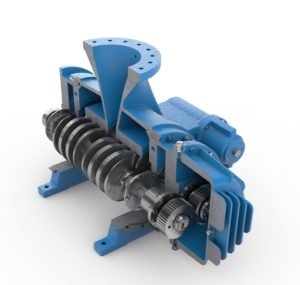

Aggregates for high pressure

Netzsch has also developed a range of Notos screw pumps which can generate pressures of up to 80 bar even in tight spaces and can cope with liquid temperatures of up to 300°C. A series of design innovations, involving the spindle profile and the pump chamber, make them particularly efficient. The sturdy metals used enable the setting of very small tolerances between the dynamic and static parts, as the components hardly deform at all in operation. This keeps backflow to a minimum and improves the ratio of pumping capacity to energy used (High Efficiency unique Design).