Mono® Confirms ATEX Compliance For Its Products

Users of Mono Pumps equipment need have no worries regarding the recently introduced ATEX Directive 94/9/EC. The company has confirmed that nearly all the products in its range comply with the requirements of the new directive, making them suitable for use in hazardous areas, for classifications up to Equipment Group II, category 2 for dust and gas.

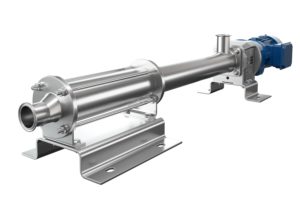

From 1 July 2003, equipment intended for use in potentially explosive atmospheres must minimise the risk of creating an ignition source if it is to satisfy the ATEX requirements. The Mono product ranges that achieve this include progressing cavity pumps and pump units, grinders, screens and packaged equipment. These products combine to create a comprehensive and extensive range of pumping and screening solutions that can be found in use in a wide variety of industries.

The ATEX directive covers equipment for use in many different types of applications, including gas, mining, oil, pharmaceutical and chemical. Other situations where the environment may contain gas or dust are also covered, such as food, wood processing, cereals and paper manufacture.

In addition to ATEX compliant equipment, for applications where specific regulations apply, such as the pumping of explosives or unstable chemicals or military applications, Mono can supply bespoke equipment that is especially designed for use in such situations, and is happy to discuss requirements with individual customers.