Metering Small Quantities

Metering processes controlled in sync with machine operating cycles place demanding requirements on the metering equipment required for this purpose.

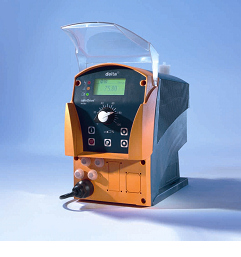

Diaphragm metering pump delta with controlled solenoid drive optoDrive

This is particularly true of applications where it is necessary to precisely apply very small quantities of a liquid within a very short space of time, i.e. virtually at split second intervals.

The cartridges are filled in an automatic production process. Automatic filling requires a metering pump that can be controlled parallel to the machine operating cycle. Metering is required in short bursts and it must also be possible to flexibly adjust the stroke volume corresponding to the size of the receptacle to be filled. A critical point is the response time between the control signals at the pump and execution of the metering stroke. The task is to meter a precisely predefined quantity of liquid within 0.5 seconds. If metering does not take place within this timeframe, the component to be filled will no longer be in the correct position and the metered medium will not land in but rather next to the cartridge.

It all depends on providing the required quantity of liquid in one stroke at the right time. For this purpose, it is necessary to correspondingly adapt the pressure stroke interval. This can be easily realised with the delta diaphragm metering pump. The controlled solenoid drive optoDrive makes it possible to correspondingly vary the metering stroke and the outlet speed of the liquid at the injection point. Since the delta® pump can execute complete individual strokes, it is the ideal pump for filling and single-drop metering applications.

Depending on the type of pump, the stroke volume can be adjusted to between 0.2 and 4 ml. Even the smallest vessels can be filled with low viscosity media without spillage.

Summing up

Filling procedures that are performed in the "conventional" way, e.g. with stainless steel piston delivery units, are relatively inflexible, intricate and expensive. The use of the delta diaphragm metering pump with controlled magnetic drive makes it possible to achieve precision metering controlled in sync with the machine operating cycle. Without the need for additional accessories, fully automatic filling procedures can be executed cleanly, reliably and precisely while largely rendering additional operations to eliminate drips superfluous.

Source: ProMinent GmbH