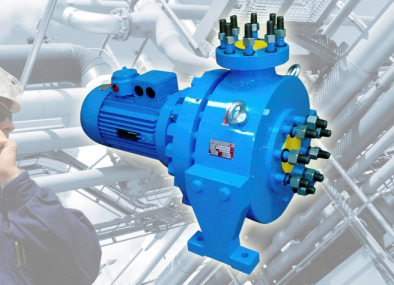

Mag-drive Pumps Meet the Toughest Challenges

Transferring aggressive, explosive and toxic liquids at high pressures safely and efficiently, are among the most difficult pumping applications. Liquids handling specialists Pump Engineering have extensive experience in providing optimum solutions for difficult pumping applications, particularly with their range of 3M magnetically driven centrifugal pumps.

Pump Engineering

The separation of these types of liquids from the atmosphere by means of an isolation shell is acknowledged as the most effective solution, while the seal-less design is the preferred choice for the chemical, pharmaceutical and petrochemical industries.

A recent example involves the CN M50-315 3M pump which has been successfully used in a research and development laboratory for an oil-field application. This required a pump to re-circulate dense phase CO2 at flow rates up to 50mc/h at 30m, with a system pressure of 200 bar. The pump was made from carbon steel with a titanium rear casing and other parts manufactured from 316L stainless steel.

3M mag-drive pumps have no glands, seals or valves and therefore provide reliable, leak-free operation, even in the most heavy-duty applications, such as pumping heat transfer oils and liquefied gases and at temperatures ranging from -150°C to +450°C. Other applications include transferring acids, alkalis, hydrocarbons, toxic and explosive chemicals in industrial and chemical industries. In the food and drink industries they are ideal for handling CIP chemicals, such as sodium hydroxide, nitric acid, hydrogen peroxide and pumping water treatment chemicals.

Source: Pump Engineering Ltd