Lovejoy Helps Plants Achieve Lubrication-Free Environment

Long-term vision is the driving force behind great engineering achievements throughout history. In today's manufacturing facilities, the plant manager who uses careful foresight and long-range planning to select replacement parts can reap both engineering and economic benefits.

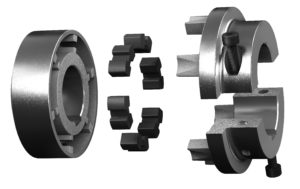

The Lovejoy®/Jaure Split-Spacer Disc coupling, or SXCS, supplies a superior design, sound engineering capabilities and long-range economic value. The closed coupling design of the split-spacer provides a superior replacement part in any application currently using a gear type coupling. In addition, this coupling requires no lubrication, a major step towards reaching the goal of a lubrication-free plant environment.

In terms of engineering performance, this Lovejoy®/Jaure part has twice the torque-carrying capability of the competition. The design is torsionally stiffer due to its spacer-wall thickness. This torque capability, combined with the coupling's zero backlash, is an especially important consideration in the printing industry, for example, when precision matters most. Additionally, bore capacity spans a wider range than is usually available, with sizes from 90-6 through 302-6 and larger sizes available upon request from the Lovejoy Engineering Department.

Economically, over time the split-spacer disc coupling more than proves its worth through cost savings associated to reduced maintenance and downtime compared to a gear coupling. Every time a gear coupling fails, once every six months or even once every three, there is no way to remove the hub and sleeve other than to shut the line down and disassemble or move driver or driven equipment. In stark contrast, after the disc coupling's initial installation, the plant maintenance staff need never move the machinery again.

The crew can check the status of the coupling's disc pack during operation with a simple strobe light. The two-piece radial removable spacer allows the end user to replace the disc pack without moving equipment, eliminating any alignment issues. Once the bolts are removed, the coupling spacer can "split" to expose the shaft. The old disc pack is easy to unbolt, remove and replace.

Time saved on overall personnel involvement is tremendous. Depending on the operation, for example, in a mill, a gear coupling change-out requires the presence of not only the maintenance crew but also the millwright and the mill electrician at a minimum.

Any industrial application currently using a gear coupling, in the paper, steel, mining, aggregate, power and wastewater industries that currently use a gear coupling can use this product as a lubrication-free replacement. Common applications include pumps, blowers or fans, conveyors, printing equipment, and coal crushers.

The Lovejoy®/Jaure SXCS has no wearing parts and this particular type of coupling has a high resistance to harsh environmental conditions. In fact, the part has infinite life if properly aligned. The 90-6 through 185-6 can provide angular misalignment equal to a gear coupling, with 1.5 degrees per flex plane. Larger models, such as the 202-6 through the 505-6 can provide one degree of angular per flex plane.

The "split" spacer-type disc coupling or SXCS offers customers just one example of the many solution-engineered products available from Lovejoy, Inc. Founded in 1900, Lovejoy enjoys an international reputation as the leading company specializing in flexible coupling design and development. Lovejoy products are available worldwide through distributors in North America and 45 other countries, supported by Lovejoy offices and support staff in Canada, Europe and the USA. Lovejoy, Inc. is certified under the ISO-9001 International Standards for Quality Management.

For more information, visit Lovejoy's Web site.

Source: Lovejoy, Inc.