Leading Supplier of Pumps for Rail Vehicles

Since 1996 KSB (Germany) has sold about 17,000 pumps from the Etaseco range for use in high-speed trains, high-performance locomotives and urban trains.

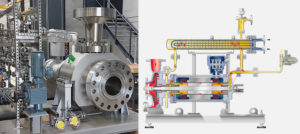

Modern high-speed trains are equipped with KSB canned motor pumps from the Etaseco series to cool the trains’ power electronics (Photo: KSB).

The pumps manufactured at KSB’s Pegnitz factory are used for cooling the power converters in traction systems.

Depending on the rated motor power, the converters for traction systems are either cooled by air or liquid. Today, the large electric drives mainly require liquid-cooled power converters.

In the cooling system, a zero-leakage canned motor pump ensures that a glycol/water mixture is circulated at a discharge pressure of up to 4 bar. The coolant temperature may vary between -50°C and +80°C max., depending on the climatic conditions.

One reason why this pump type has been so successful in these applications is that it meets high requirements with regard to quality, vibration characteristics, noise levels, service intervals and MTBF value (Mean Time Beween Failures).

Before the pump is actually used in railway applications, it has to undergo comprehensive testing to prove it is compliant with EN 60349-2 and EN 61373.

KSB pumps are currently employed in locomotives in countries all over the world, such as

- Australia (Queensland)

- Belgium

- Bulgaria

- China (DJ8, DJ4, CHN)

- Denmark

- Germany (ICE-3, BR 426-426, BR 185.2, BR 189)

- France (TGV–POS, NAT)

- Great Britain

- Italy (E464, AGV)

- Korea

- Lithuania

- Austria (ÖBB 1016/1116, 2016)

- Portugal

- Russia

- Switzerland (Zurich urban train)

- Spain

- USA (NJT).

Source: KSB SE & Co. KGaA